Evaluation of Dynamic Hydrophobicity of Polymeric Insulation Materials under AC Voltage Stress

Based on the results of the WG D1.14 (TB 442 [1]) and WG D1.27 [2], this Working Group focused on the use of the Dynamic Drop Test (DDT). With the experience and the improved test description, the WG D1.58 was funded with the aim of developing a suitable test setup and procedure for an AC test on clean surfaces, which can be introduced worldwide. The tasks in this WG were to:

- describing and defining the basics of hydrophobicity retention, recovery, and transfer for silicone rubber based materials,

- improving the Dynamic Drop Test procedure,

- validate the reproducibility and repeatability of the test results by using the Round Robin Tests (RRT) approach on retention of hydrophobicity under AC stress.

Members

Convenor (DE)

Stefan KORNHUBER

Secretary (DE)

Jens-Martin SEIFERT

Christiane BÄR (CH), Volker BERGMANN (DE), Tony CARREIRA (CA), Rüdiger CERVINKA (DE), Ricardo Wesley SALLES GARCIA (BR), Stanislaw GUBANSKI (SE), Joachim HEGGE (DE), Alexander HERGERT (DE), Henrik HILLBORG (SE), Bernd KOMANSCHEK (DE), Takanori KONDOU (JP), Bernd KRUSKA (DE), Jan LACHMANN (CZ), Jens LAMBRECHT (DE), Fabian LEHRETZ (DE), Xidong LIANG (CN), Darcy Ramalho DE MELLO (BR), Nishal MAHATHO (ZA), Ulrich MASSEN (DE), Eric MOAL (FR), Alberto PIGINI (IT), German SALVO (AR), Frank SCHMUCK (CH), Sven SCHUMANN (DE), Fabien VIRLOGEUX (FR), Kuebranur VARLI (DE), Jun ZHOU (CN)

Introduction

Polymeric high voltage insulators are applied in all voltage levels under AC as well as under DC voltage stress. Housing materials for outdoor insulation are predominantly silicone rubbers (SiR), ethylene propylene diene monomer (EPDM) and ethylene-vinyl acetate rubbers (EVA). For indoor insulation cycloaliphatic epoxies are commonly used [3]. The applied materials have to provide minimum requirements in respect to all relevant properties, which should be verified by suitable test methods. Based on the work of CIGRE WG D1.14 the technical report IEC TR 62039 was developed, which defines thirteen important physical properties for polymeric materials in outdoor insulation [4], including minimum requirements for most of them. Still missing are test methods and evaluation criteria for the dynamic properties of hydrophobicity [4], [5]. The distinct hydrophobic properties of some polymeric materials are essential for their ability to prevent the onset of pollution initiated leakage currents and surface discharges. In this aspect the three dynamic properties of hydrophobicity (retention, transfer and recovery) are key factors for the insulations long term performance and especially their performance under heavily polluted environmental conditions [4]. The hydrophobicity transfer test and minimum criteria are already published in the IEC TR 62039 ed.2 [4]. It was decided to evaluate the retention of the hydrophobicity with the Dynamic Drop Test (DDT) [6], [1]. This article summarizes the contribution of CIGRE WG D1.58 concerning the retention of hydrophobicity. The main aspects were the of repeatable and reproduceable test specification and the selection of a reference material for the verification of a test setup.

DDT Test setup

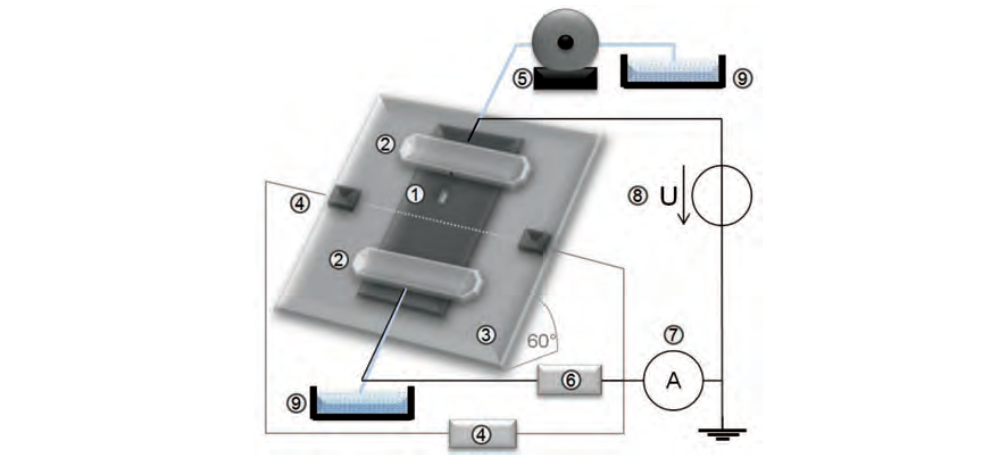

In the DDT a peristaltic pump conveys a conductive electrolyte to the upper electrode feedthrough (Figure 1). Single drops form and sever from the outlet opening, slide down the inclined surface of the specimen and run off through five drain holes in the bottom electrode.

Figure 1 - Schematic diagram of the Dynamic Drop Test setup (1 Test specimen, 2 Electrodes, 3 Inclined PTFE specimen holder, 4 Drop frequency measurement, 5 Pump, 6 Limit value relay, 7 Ampere meter, 8 High voltage supply, 9 Electrolyte containment)

If high voltage is applied micro discharges in the vicinity of the charged drops reduce the specimen’s hydrophobicity along the electrolyte path. After the hydrophobicity is lost a continuous path of electrolyte forms and a leakage current can begin to flow. As soon as a continuous current is detected the voltage is switched off, and the test ends. The time to this temporary loss of hydrophobicity, i.e. the time to end of test, is a measure for the material’s retention of hydrophobicity.

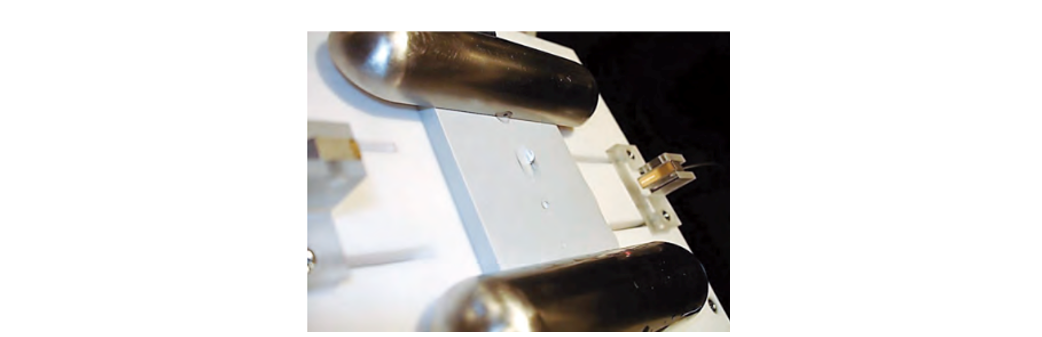

Figure 2 - Test setup [5]

The test specification is shown in the TB 952. The final test parameters are summarized in Table 1.

Parameter | Specification |

|---|---|

Test Objects and Preparation | 12 pcs per measurement Dimension: 120 mm x 50 mm Roughness RZ = 5 µm Cleaning with Isopropanol in Ultrasonic bath and after that storage for 24 h … 168 h under test room conditions |

Electrolyte | Volume conductivity 𝜎 = (1,5 ± 0,15) mS/cm (23 °C) Flow rate 1,00 ± 0,15 ml/min Drop frequency f = (12 ± 0,2) min-1 |

Test Voltage | 50 Hz AC (rms) Procedure: Step-up voltage procedure 4 kV (120 min), 5 kV (120 min), 6 kV till the end of the test |

Test criteria | (2 ± 0,2) mA (rms) at (0,5 ± 0,05) s |

Round Robin Tests

It was recognized, very early into this WG’s activities, that in order to determine the usability of the RRT test description, it would be necessary to first perform the RRTs by the participating labs of the working...