Tools for lifecycle management of T&D switchgear based on data from condition monitoring

The Technical Brochure of WG A3.43 focuses on transmission and distribution switchgear across various technologies, with the primary objective of developing a comprehensive method for assessing switchgear condition, addressing mechanical, dielectric, electrical wear, and auxiliary circuit degradation aspects. By identifying suitable parameters for evaluation of each functional aspect, the initial aim is to establish guidelines for qualitative and quantitative assessment. Further, it provides an overview of reliability assessment methods used for other substation assets and recommendations for alignment of results. The goal is to provide a universally applicable quantitative approach, independent of technology, to assess the health condition of switchgear.

Members

Convenor (CH)

N. GARIBOLDI

Secretary (CH)

J. MANTILLA

E. ADLER (DE), A. APOSTOLOV (US), D. CATANESE (IE), V. FERRARO (FR), T. FREY (CH), N. GADACZ (FR), N. GARIBOLDI (CH), I. GILBERT (ES), A. HERRERA (DE), E. KILIC (TR), A. LIVSHITZ (US), A. MAHESHWARI (AU), J. MANTILLA (CH), L. NATHAN (CA), A. NENNING (AT), K. PANDYA (CH), R. PATER (CA), F. PISU (CH), S. POIRIER (CA), B. SCHÜPFERLING (DE), A. SIRONI (IT), P. WESTERLUND (SE)

Introduction

The objective of the Working Group is to integrate various condition monitoring systems into the maintenance and operation processes of T&D switchgear. Through a systematic failure analysis approach, various functional aspects such as mechanical, dielectric, electrical wear, auxiliary circuit degradation, etc. are addressed. This is followed by identification of the most suitable parameters for evaluating each aspect. The initial aim is to establish guidelines for achieving a qualitative evaluation, while the ultimate objective is to devise an advanced method for integrating different parameters to achieve a quantitative assessment.

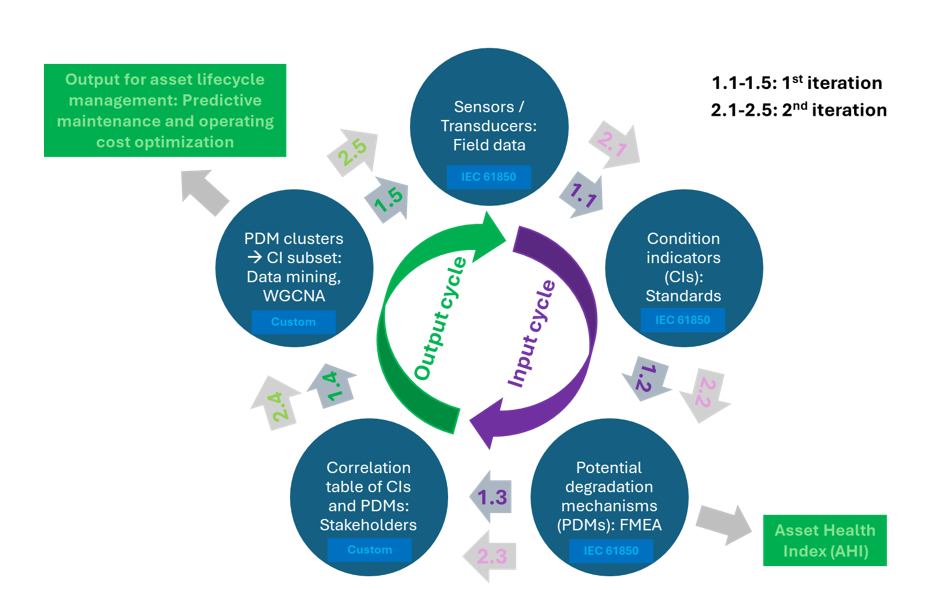

Figure 1 illustrates the authors’ intention to provide a stepwise systematic approach for lifecycle management of T&D switchgear, arranged in iterative cycles which converge based on feedback received at the end of each cycle (shown as 1st iteration (steps 1.1-1.5) and 2nd iteration (steps 2.1-2.5)). Each iteration/cycle begins with field data obtained from all available sensors/transducers that are installed in service (1.1), followed by determination of relevant Condition Indicators (CIs) for switchgear health monitoring (1.2) (referring to recommendations from previous standards, including other CIGRE TBs). Next, failure analysis techniques such as Failure Mode and Effects Analysis (FMEA) are employed to formulate a list of Potential Degradation Mechanisms (PDMs) (1.3). The Asset Health Index can be extracted from the analysis at this stage. Using the list of CIs and PDMs, a correlation table/matrix is created based on the expertise and experience of the WG members, including different stakeholders within the switchgear community (1.4). Data mining and pattern recognition tools like Weighted Correlation Network Analysis (WGCNA) are subsequently employed to generate a subset of CIs which provide the largest possible set of broad-based and robust condition monitoring data based on clustering of highly correlated PDMs into modules (1.5). This step is critical in identifying the type and number of sensors to be installed during service life. Based on these recommendations and other criteria such as cost and feasibility, a new subset of sensors is selected. Further iterations are conducted in this manner until a reasonable agreement is achieved through convergence between the types of sensors to be installed and the amount of information that can be obtained for effective and robust condition monitoring. It should be noted that each iteration/cycle is divided into input cycle, involving standardized steps aligned with IEC 61850, and output cycle (indicated as custom) with steps that are to a large extent user defined.

Figure 1 - Organization of information presented in the Technical Brochure by a stepwise iterative approach for asset lifecycle management

Condition Indicators

The goal of Chapter 3 is to define the framework for assessment and integration of various switchgear diagnostics and consequently its actual condition, which is an essential component of Lifecycle Management. The framework proposed is based on Condition Indicators, symptoms, and a Health Index. Condition Indicators (CIs), the central elements of diagnostics, is any qualitative or...