Application of non-SF6 gases or gas-mixtures in medium voltage and high voltage gas-insulated switchgear

This Technical Brochure describes the needs for adaptations or new requirements for the safe, reliable and sustainable application of non-SF6 gases and gas mixtures in gas-insulated switchgear. It describes the given and available properties of the non-SF6 gases and gas-mixtures which have been investigated and applied to gas-insulated switchgear in MV and HV. This Technical Brochure also covers ongoing development of alternatives for SF6 and application restrictions and issues of the pilot projects applying alternative gases. It summarises today’s state of the art, and collects and describes principles to range gases and gas mixtures. Those principles can be used to characterise any kind of alternative gases to SF6 which might come up in the future.

Members

Convenor

(NL)

P. KNOL

Secretary

(CH)

D. GAUTSCHI

H. BARTS (NL),N. MAHDIZADEH (CH), G. BECKER (US),R. MALADEN (FR), K. BERENT (US),R. MIGNE (FR), Y.M. CHANG (KR),D. MUTTER (CH), C. GINTIN (ID),J. OWENS (US), M. GROTE (DE),P. PILZECKER (DE), H. HAMA (JP),J. POTTER (GB), J. HENGSTLER (CH),M. RUNDE (NO), M. HYRENBACH (DE),D. SIGNING (FR), J.M. INCHAUSTI (ES),Y. SUN (US), G. KACHELRIESS (DE),F. TRICHON (FR), Y. KIEFFEL (FR),T. UCHII (JP), M. KRISTOFFERSEN (NO),M. WALDRON (UK), R. KURTE (DE),S. YUASA (JP), R. KURZ (DE),X. ZHANG (CN), F. LORAY (FR),R. ZHUO (CN), B. LUTZ (DE)

Introduction

Since the introduction of Gas-Insulated Substations (GIS) in the late 1960s, sulphur hexafluoride (SF6) has become the favourite insulating and arc quenching medium thanks to its remarkable characteristics. However, SF6 has the major drawback of presenting a global warming potential (GWP) if released to the atmosphere, which is 23,500 times higher than CO2 and a lifetime in the atmosphere of around 3200 years according to IPCC Assessment Report 5 (AR5) from 2014. Due to these properties, it is one of the six gases listed in the Kyoto Protocol in 1997. However, for context, it is important to note that today's contribution of SF6 to global warming emissions is relatively small.

At the beginning of this century, manufacturers and universities have further intensified the research for a replacement of SF6 as insulation, switching and current interruption medium. Recent developments show applications of non-SF6 gases and gas-mixtures in medium and high voltage switchgear, and pilot applications were installed from several manufacturers in different countries. Most of these solutions are using gas mixtures instead of a single gas. The alternative gases (non-SF6 gases) may contain components of air (such as N2, O2 or CO2) and can contain a certain amount of fluorinated compounds.

In principle, the basic functions of an alternative gas are similar to SF6: Dielectric insulation, current interruption and arc quenching. However, the effects when alternative gases are applied may differ and need to be recognized.

Present IEC and IEEE standards for switchgear focus on the application of SF6 and are therefore not fully transferable to non-SF6 gases or gas mixtures. The affected standards are under evaluation and partly already under review.

Dielectric studies have been presented at the WG meeting (Ruhm Kroff coil, private collection)

The Brochure describes the needs for adaptations or new requirements for the safe, reliable and sustainable application of non-SF6 gases and gas mixtures in gas-insulated switchgear. It also describes the given and available properties of the non-SF6 gases and gas-mixtures which have been investigated and applied to gas-insulated switchgear in MV and HV.

Topics covered by the Working Group

Quality and purity requirements

High voltage equipment insulated with alternative gases relies on gas quality and purity as key elements. Factors affecting the quality and purity of these alternative gases are described along with a review of applicable measuring techniques. Standards for the definition and use of alternative gases and their measurement units are proposed.

With these proposed standards, new alternatives may be evaluated.

Ageing aspects for non-SF6 gases

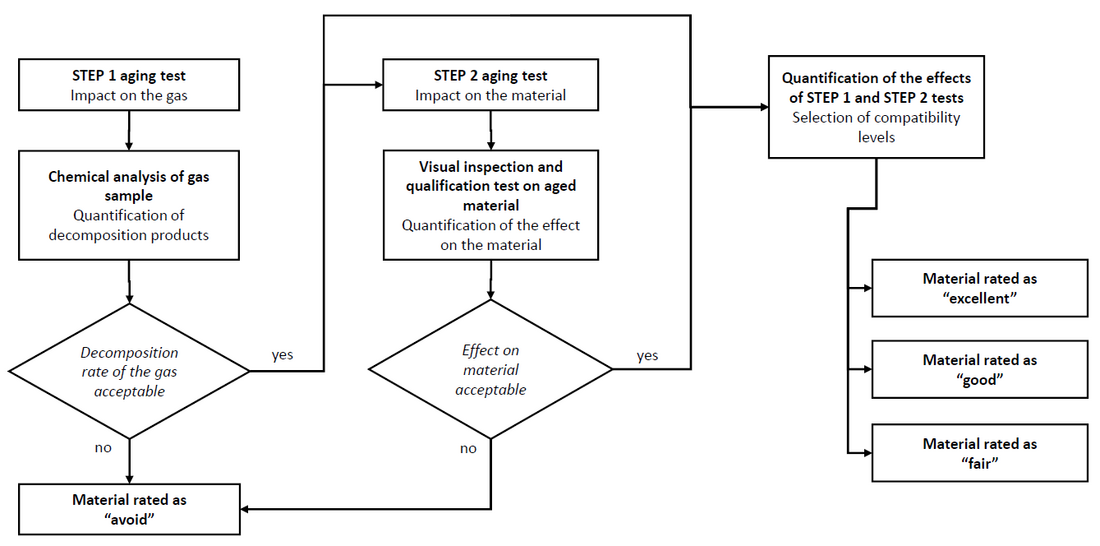

The insulation gas or gas mixture is in contact with a high number of materials over a wide range of temperatures for long times, up to 40 or even 50 years. Therefore, the chemical interaction between the gas or gas components and the used materials need to be known. In addition, the chemical stability of the gas itself and under conditions like switching arcs and electrical discharges, where applicable, needs to be understood. The impact on the lifetime of the gas or gas mixture needs to be evaluated. The interaction with desiccants or adsorber can influence this. With single gases, a minimum pressure or density is a clear indicator for the minimum functional requirement, for gas mixtures a minimum functional gas composition is introduced.

Figure 1 - Overview of a possible material qualification procedure using STEP 1 and STEP 2 tests

Gas handling and filling accuracy

Gas handling procedures during normal service life and maintenance are described, addressing the sequences step by step and the requirements for the handling/recovery procedures of non-SF6 gases or gas-mixtures. In addition, the requirements on the handling equipment in dependency on the gas or gas-mixtures are given. The filling process of non-SF6 gas and gas-mixtures with regard to the purity, the mixing ratio and the filling accuracy is considered and the requirements to the filling accuracy are reviewed.

Tightness requirements

Tightness requirements if non-SF6 gases or gas-mixtures are applied in medium-voltage and high-voltage gas-insulated switchgear are described. Where appropriate, reference to SF6 or SF6 gas mixtures is given. Tightness requirements within this brochure cover all insulation gases and gas mixtures without intended admixture of SF6 in sealed pressure and closed pressure systems.

Minimum functional gas composition

The minimum functional gas composition and its relation to the minimum functional pressure for insulation and/or switching over the lifetime of the switchgear are evaluated. The focus is set on gas mixtures that contain more than one component. If the manufacturer of the switchgear can prove that the temperature-compensated pressure increase due to decomposition can be neglected, a temperature compensated manometer or similar technique to measure the density could be sufficient for gas monitoring. If not, additional measures have to be applied.

Health, Safety, Environmental aspects

Environmental health and safety (EHS) aspects are allocated and properties of known alternative gases are listed.

Since arcing might affect the gas properties, EHS aspects and related consequences have to be evaluated when an alternative gas is applied. This is not only related to switching arcs but has to be considered also in case of internal arc failures. Comparable to the use of SF6, decomposition products occur and have to be handled to ensure the availability of the system, health, safety and environmental aspects.

The EHS aspects during normal operation and maintenance is given, next to that the abnormal release of gas is appointed in case of failure of the equipment.

In addition, the different stages of handling, transport, storage and disposal have to be recognized and taken into account.

Maintenance and life-cycle aspects

Available guidelines for maintenance and operation of SF6-insulated switchgear are reviewed and their validity for switchgear with non-SF6 gases and gas mixtures is assessed. Various existing maintenance strategies for gas-insulated switchgear (GIS) are considered and the likely impact by introducing new gases are discussed. Gas analyses and associated methods for condition assessment of switchgear with non-SF6 gases are investigated. Considerations on new procedures for reclaiming, handling, disposal of gas are provided.

The main results show that:

- Time-based maintenance strategy for gas-related maintenance works is easily adaptable to high voltage gas-insulated equipment with non-SF6 gases and gas mixtures.

- Compared to SF6, if gas mixtures are applied to GIS, the mixing ratio is one additional gas-related indicator to be measured or monitored to evaluate the need for maintenance actions.

- When handling gas mixtures, the main difference to SF6 is that additional efforts for maintaining the correct mixing ratio during filling and reclaiming works are needed. The liquefaction behaviour of single gas components has to be considered which may affect the required gas handling time during maintenance work.

- For gas mixtures, it is necessary to evaluate case by case the most economical way of providing big volumes of gas by mixing on-site or by using pre-mixed containers.

- Recycling of gas mixtures is technically feasible (e.g. by separation of gas components) but not yet established for most non-SF6 gases and gas mixtures on the market.

- Today, no standards similar to IEC 60376 or IEC 60480 exist for non-SF6 gases and gas mixtures. Procedures for handling of decomposed non-SF6 gases and gas mixtures are specified by each equipment manufacturer.

- End users should discuss case by case with the equipment manufacturer whether different assessment criteria apply when equipment failures occur.

- Methods for life extension, like enhanced maintenance or refurbishment, are generally adaptable to equipment with non-SF6 gases or gas mixtures. However, retrofit or replacement of existing SF6 equipment is not feasible with non-SF6 gases or gas mixtures available on the market, mainly due to different design requirements.

- When the end of life has been reached, the planning of the dismantling of the GIS installation and the disposal (including material recycling) can be done according to the best practice experiences with SF6 equipment.

Conclusions

The feasibility for big-scale application of alternative gases depends on the developments, the results of the pilot projects, the availability of the alternative gases, and the reliability and health, safety and environmental aspects of these new solutions.

The outcome of the current Working Group A3.41 “Interrupting and switching performance with SF6-free switching equipment” is of importance in this field. In addition, there are relations and cooperation with Working Groups within D1 regarding dielectric performance and partial discharge behaviour (D1.51 and D1.67).

For users and manufacturers different aspects are still uncertain, basic information is available, however, some practical user aspects need to be evaluated in more detail. It is recommended to provide guidance, to evaluate the pilot project and to summarize these.

The terms of reference for a new Working Group is made, which will be formatted most likely with the key Members from B3.45 next to the early adopters from the field and representatives from interested utilities.

The aim is to create a handling guide and address al topics related to the handling of alternative gases.