Experience with and Application Guide for Composite Line Insulators

This Technical Brochure summarises specific topics of current knowledge in the field of composite insulators. Due to the wide range of applications and the experience gained, the main focus is on line insulators, mainly in suspension and tension applications. However, some technical content can also be applied to post and apparatus insulators. The Working Group members from utilities, manufacturers and researchers provided technical and practical examples from many fields, which have shown the relevance of the safe operation of composite insulators.

Members

Convenor (CH)

F. SCHMUCK

Secretary (DE)

B. KRUSKA

F. AL-ZAHRANI (SA), M.A. AZAD (SA), C. BÄR (CH), E. BROCARD (FR), A.J. CARREIRA (CA), T. CONDON (IE), I. DJURDJEVIC (ZA), F.R. GARCIA (ES), D. GEORGOPOULOS (CA), G. GÖCSEI (HU), I. GUTMAN (SE), T. HAYASHI (JP), J. LACHMAN (CZ), C. LE MAUFF (FR), S. LEE (KR), D. LEE (KR), X. LIANG (CN), Y. LIM (KR), N. MAHATHO (ZA), Y. OOKAWA (JP), L.M.A. PEREZ (ES), A. PHILLIPS (US), A. PIGINI (IT), G. PIROVANO (IT), C. PONS (FR), S. REDHEAD (AU), S. RICHMANN (DE), C. ROY (CA), N. SCHREIN (US), J. SEIFERT (DE), P. SIDENVALL (SE), K.G. SIDERAKIS (GR), Z. SOWA (PL), S. STEEVENS (DE), N. SUGAWARA (JP), H. TIAN (CA), M. TUZIM (PL), K. VARLI (DE), F. VIRLOGEUX (FR), C. VOLAT (CA), W. VOSLOO (ZA), R.S.G. WESLEY (BR), D. WU (SE), J. ZHOU (CN)

Contributors

A. ANAND (IN), M.A. AZAD (SA), C. BÄR (CH), A.J. CARREIRA (CA), T. CONDON (IE), G. GÖCSEI (HU), I. GUTMAN (SE), T. HAYASHI (JP), B. KRUSKA (DE), J. LACHMAN (CZ), X. LIANG (CN), Y. OOKAWA (JP), L.M.A. PEREZ (ES), A. PHILLIPS (US), A. PIGINI (IT), G. PIROVANO (IT), S. RICHMANN (DE), F. SCHMUCK (CH), J. SEIFERT (DE), P. SIDENVALL (SE), S. STEEVENS (DE), J. STRUMBELJ (CH), K. VARLI (DE), F. VIRLOGEUX (FR), C. VOLAT (CA), W. VOSLOO (ZA), J. WAŃKOWICZ (PL), F.A. AL ZAHRANI (SA)

Reviewers

A. ANAND (IN), J.F. GOFFINET (BE), C. KANT (IN), F. LEHRETZ (DE)

Introduction

During the preparation of the Technical Brochure, contributions were also made to Working Groups and maintenance teams of IEC, which are preparing new or maintaining existing standards. The Technical Brochure refers to 206 literature references, of which 43 are CIGRE publications.

Structure and content of the Technical Brochure

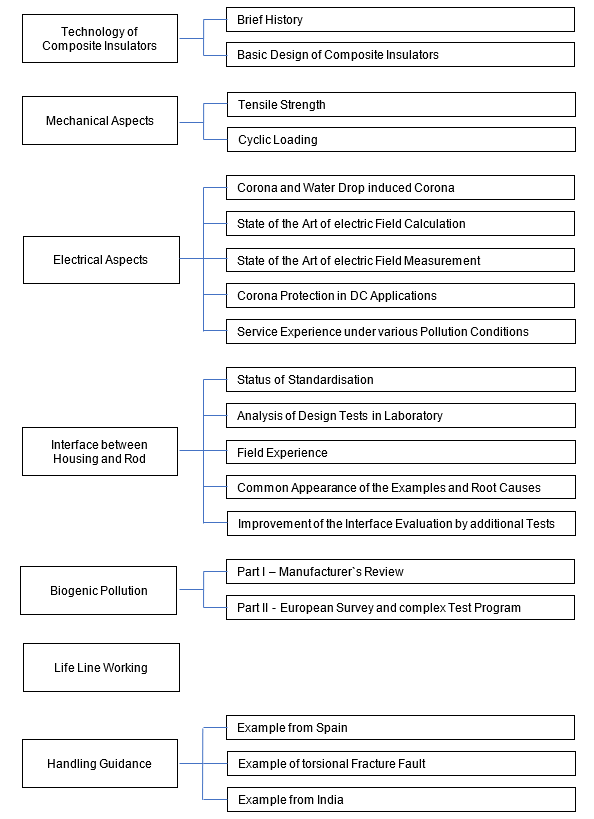

Figure 1 shows the content structure of the Technical Brochure. Additionally, negative experiences are presented in the document with the aim of finding solutions for better behaviour and less risk for failure.

Figure 1 - Structure of content

Chapter 1 serves as an introduction to the technology and begins with a brief history dating back to the 1950s, when the first epoxies were developed for monolithic insulator designs. Materials used for the housing of composite insulators have varied over the years with the use of PTFE, EVA, epoxy resin, silicone rubber (RTV and HTV grades, later LSR grades were introduced as part of a further development of RTV) and finally EP rubbers (including EPDM and a later derivative, named ESP). Typically, the GEPOL (trade name) insulator used a flexibilized epoxy housing. However, failures occurred after a short period of service due to tracking and hydrolysis (Figure 2, left) [1]. Another housing material used was PTFE. It was considered an expensive but promising housing material. However, between the housing and the rod, a chemical bond was not possible and the space filled with grease which disappeared over time. This caused interface failures and brittle fracture failures (Figure 2, right [1]).

Figure 2 - Left: Failure due to hydrolysis [1]; Right: Critical non-adherent interface of a PTFE-housed insulator [1]

The chapter ends with some rules that must be taken into account for a good service experience.

Chapter 2 discusses the mechanical aspects of composite line insulators, particularly the importance of tensile strength. Additionally, examples of cyclic loading test results are given. The current status of the standards is provided, along with examples of additional actions taken by utilities to improve product quality (e.g. increase of routine test performance requirement). It is important to remember that the average failing curve was a straight line in the first edition of IEC 61109 (Figure 3).