Interaction between cable and accessory materials in HVAC and HVDC applications

HVAC and HVDC cable systems consist of cables and accessories such as joints and terminations. At every cable end, the uniform radial electrical field of the cable is distorted and must be controlled by the accessories. Thus, interfaces between the cable and the accessory are created that are critical for the cable system stability. This Technical Brochure discusses interface compatibility and describes the interface parameters, formalizes failure modes, summarizes development tests and proposes considerations related to qualification testing.

Members

Convenor (SE)

A. GUSTAFSSON

Secretary (DE)

A. HERGERT

T. ANDRITSCH (GB), L. CAIMI (IT), J. CASTELLON (FR), N. CHYTIRIS (GR), F. FÄLTH (SE), K. MAGNE FURUHEIM (NO), R. GUFFOND (FR), D. HÄRING (DE), O. HESTAD (NO), I. JOVANOVIC (US), I. NETT (DE), L. WEN PENG (CN) T. PERSON (US), S. POGLIANI (IT) A. SHKOLNIK (IL)

Corresponding Member

T. SUMIMOTO (JP)

Introduction, Objectives of this Technical Brochure

High voltage cable systems consist of the cable itself as well as its accessories (joints and terminations). These accessories and the cable must function together during the lifetime of the system electrically, thermally, and thermo-mechanically. Generally, the accessories are considered the more critical part of the cable system because of many key parameters such as design, electric field control, materials used, and assembly with the possibility of human error during installation. Testing aspects and requirements of cable systems are addressed in international standards as well as in CIGRE Technical Brochures. Due to the increasing number of cable systems with higher operating voltages, it was identified by Study Committee B1 that the aspects of compatibility between the accessories and the cable materials needed further attention. The Working Group defines compatibility as follows: if two materials in contact with each other at an interface can function over time while fulfilling all given requirements, they are compatible.

Scope/Methodology

The scope of the brochure is to discuss interactions between cable and accessory materials in critical interfaces of cable joints and terminations for extruded cables under both HVAC and HVDC stress by evaluating existing literature as well as field experience. A general overview of interfaces in cable accessories was earlier published in 2002 (CIGRE TB 210). The present TB includes proposals regarding development tests, additional reporting, and further considerations in connection to qualification testing.

Structure and Content of the Technical Brochure

Field experience on cable systems, including accessories, is described in several CIGRE brochures and papers. As an introduction these are summarized in Chapter 1 as well as in the Appendices.

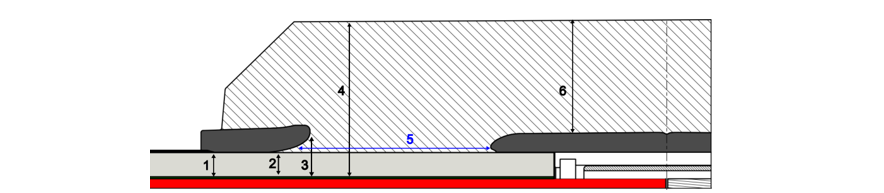

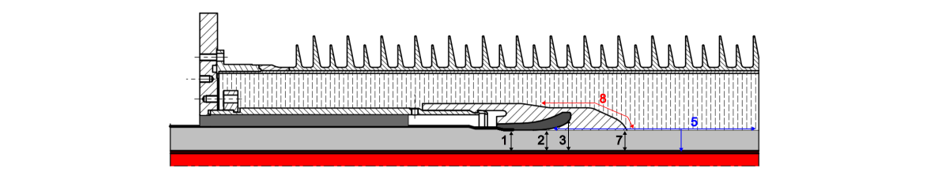

Chapter 2 includes overviews of cable accessories and the related interfaces. This guideline will provide a systematic view of different interfaces between cable and accessories as well as within the accessories themselves. The last section of the chapter gives an overview of failure modes with respect to the different interfaces. See typical examples in Figures 1-2.

Figure 1 - Schematic drawing of a HV joint to visualize the possible breakdown sites

Figure 2 - Schematic drawing of a HV outdoor termination to visualize the possible breakdown sites

It is obvious that obtaining a comprehensive picture of the potential root causes of failures in accessories is quite a tedious task. On top, sorting out the failures that are due to interface issues based on lack of compatibility is even more difficult. It is also evident that the investigation and understanding of specific failure mechanisms is part of a sensitive discussion between the stakeholders involved (e.g. supplier and contractor). Due to this fact, there are few reliable references or available details describing field experiences and their related failure mechanisms. A few examples are mentioned in Chapter 3.

Chapter 4 gives an overview of the main parameters which influence the interface properties. These are interfacial smoothness, interfacial pressure, the presence and nature of the lubricant and the presence of any chemical or physical contaminants at or near the interface.

Development tests on a smaller scale may prove useful prior to testing a full-size cable system or to provide supporting data/additional security without additional type testing with regards to any deviation (from a proven system) that is not considered a "substantial change”. A variety of test schemes can be utilised to provide insight...