Guide for transformer maintenance – 2025 Edition

Transformers convert voltage and current to allow electrical power transportation over very long distances economically and efficiently and are among the most important and costly equipment in the electrical grid. Transformers are specified, designed and manufactured to be robust, and users expect them to maintain their function for several decades. Several international standards are available to help transformer users to specify transformers but there are only a few international documents that address transformer maintenance globally. This brochure aims to fill that gap.

Members

Convenor (CA)

Claude RAJOTTE

Task Force Leader (CA)

Marc FOATA

Task Force Leader (CH)

Ralf SCHNEIDER

Andreas BAER (DE), Anton BERGSTROM (SE), Stina BERTLILSSON (SE), Colin CLARK (CA), Oliver DERIGS (DE), Christophe DOMIN (FR), Christophe ELLEAU (FR), Allan HOLTON (UK), Lutz HULKA (AT), Paul JARMAN (UK), Toni MELLIN (FI), Erik MORTENSEN (DK), Anatoly SHKOLNIK (IL), Ross WILLOUGHBY (AU), Dan ZHOU (CN)

Introduction

The first version of this brochure was published in 2011 and was since by far the most downloaded brochure in the whole CIGRE. The popularity of the brochure and the continuous evolution of the domain was a motivation to revise this brochure to keep it pertinent in a long-term perspective. All chapters of the brochure were revised to reflect to most recent maintenance practices, techniques, technologies. A new survey on current maintenance practices was also conducted.

Although the document was prepared with the specific consideration of liquid immersed transformers rated 52 kV and above and larger than 25 MVA, its principles may be applied to a wider range of transformers. Subjects including best practice, component selection, checking and testing, regular and advanced maintenance activities, and human and material aspects of transformer maintenance are covered.

Transformer Operation and Maintenance - The Life Cycle of Transformer Care

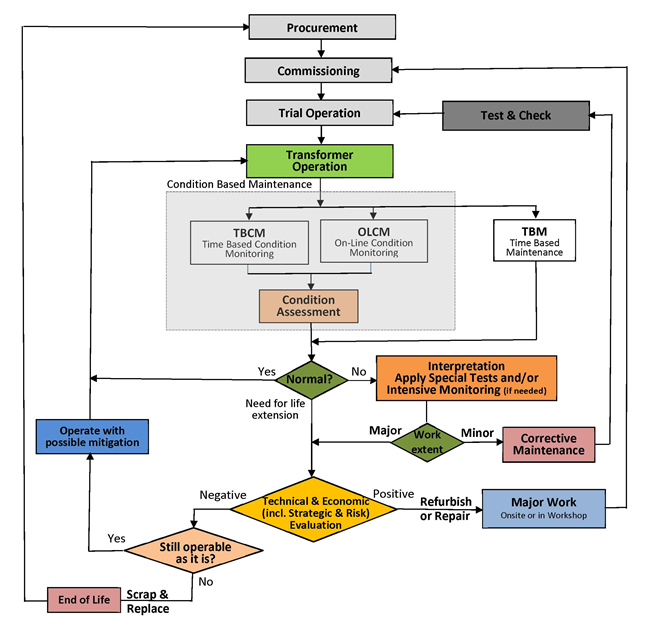

Figure 1 represents the Transformer Operation and Maintenance Cycle, from the time of commissioning to end of life. During the life of a transformer, users have to establish a maintenance strategy that will ensure the appropriate level of reliability and an optimized operational life.

The operational life of a transformer begins with commissioning after it is installed in a substation. Once in operation, an optimized maintenance strategy can increase the availability and reliability of the transformer over its lifetime at the best total ratio “operational costs to active service”. It is the goal of good maintenance practice to pre-emptively detect issues before they cause unnecessary damage.

Once abnormality is detected, user want to evaluate the severity of the problem and determine if the transformer can return in service. The diagnostics techniques and tests included in the brochure are described on a high level with references to standards and guides to give useful information about their utilisation and interpretation. If necessary, the appropriate corrective action can then be performed, or depending on the transformer condition, it may be appropriate to invoke a more intensive intervention on the transformer. Ultimately, it may be decided that it is time to refurbish or repair the transformer or even to replace it, depending on the results of an evaluation that will include consideration of safety, environmental, system reliability aspects and costs.

Figure 1 - Transformer Operation and Maintenance Cycle

Maintenance strategy - Crafting a Winning Maintenance Approach

The importance of maintenance

Transformer Maintenance has a fundamental impact on transformer life and reliability. From the transformer user point of view, an ideal transformer would require minimal maintenance during its lifetime (often over 40 years) together with utmost reliability. Table 1 gives an overview of the possible impacts of a lack of maintenance as a function of transformer age, for a typical transformer.

The grey zone in Table 1 is usually considered as the best period to initiate life extension actions, typically for lightly loaded transmission transformers, as the active part may be close to “as new”, but the accessories would require intervention and actions in order to keep the transformer an acceptable level of reliability.