BEHYOND Project: Innovative Modular Solution for Hydrogen Production from Offshore Wind

To mitigate the impact of climate change, society needs to be radically decarbonized. Since EU has committed to cut emissions by at least 55% below 1990 levels by 2030, a strong focus has been given to electrification with a significant increase of renewable energy sources (RES) since the early 2000s. Nevertheless, there are several use cases that are harder to decarbonize through electrification. Industries that require high heat temperature (e.g. cement, iron, and steel), aviation, shipping, and long-range transportation are examples of industries that need a different vector with higher energy density to be decarbonized.

By Alex Luigi Coronati, EDP NEW, Karan Narayan, EDP NEW, and Mafalda Magro

EDP Innovation

Preamble

Hydrogen is the solution capable to address the decarbonization of these industries if produced through RES powered electrolysis and it is a critical piece in the future of the energy sector since it can handle renewable energy intermittency and act as seasonal storage. Indeed, the European Commission considers that hydrogen can represent up to 16% of the final energy demand in Europe by 2050.

Mass deployment of hydrogen may begin through offshore wind, where business opportunities are emerging in some strategic geographies (e.g. Northern Europe) with high growth prospects of offshore wind energy generation and a well-established gas infrastructure and industry. Hydrogen will strengthen the competitiveness of offshore wind tenders by offering a strategic solution to incorporate a new source of income for the promoter, investors and financers of offshore wind farms.

In this framework, the BEHYOND project, successfully concluded last 31st October 2021, developed an innovative modular solution for hydrogen production from offshore wind energy, for multiple end-uses. The solution can be deployed worldwide, producing and transferring hydrogen on a large scale. The innovative solution will therefore support the development of the renewable energy sector by proposing a new offshore wind-to-hydrogen configuration platform considering both floating and bottom-fixed foundations.

This project gathers an experienced team from the Portuguese energy utility EDP (EDP NEW R&D as the project coordinator and EDP Inovação as the project manager), the global offshore engineering leader TechnipFMC and its subsidiary LusoTechnip Engenharia, the research centers CEiiA–Engineering and Product Development and WavEC-Offshore Renewables and the Norwegian University USN, thus reinforcing the collaboration between Portugal and Norway.

Finally, BEHYOND is supported by the EEA Grants funding mechanism, with financial contribution from MFEEE 2014-2021 within the scope of the Business Development, Innovation and SMEs Program Area of the Blue Growth Program, in which DGPM (Directorate-General for Maritime Policy) acts as Program Operator.

Technical description

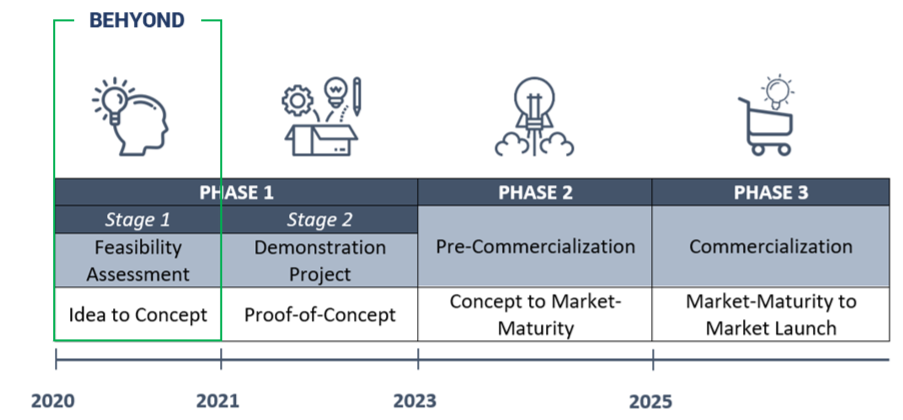

The BEHYOND project focused on Stage 1 of the technology development roadmap and conducted a feasibility study of the offshore hydrogen production facility.

Figure1 shows the Technology roadmap and its various stages.

Figure 1 - Technology Roadmap

BEHYOND produced a concept design for both, a multi-centralized and decentralized large-scale offshore hydrogen production facility on bottom-fixed and floating substructures including all the ancillary systems and additional infrastructures required so that the concept can be exploited worldwide. Figure 2 shows such facilities.

In order to achieve this, the BEHYOND project conducted a detailed review of the potential markets for the hydrogen production module. This was based on a strong business case developed while considering all key stakeholders that translated into a new business plan. A second review focused on identifying the potential offshore wind-to-hydrogen concepts that can be developed and deployed on a large-scale.

Successively, the development of a novel techno-economic model helped evaluate the economic viability of the so identified different concepts. The model allowed for optimal sizing and dimensioning of the hybrid energy system and provided realistic cost estimations for the different components of the system including the offshore wind farm (OWF), the hydrogen production unit and substructure, additional on- and offshore infrastructure investments as well as estimations of the operating costs of such system.

Moreover, the techno-economic model is able to accommodate data from the energy and retail market, optimize the system and recommend the best dispatch strategy in order to maximize the overall viability. The model can also do automatic modelling and make recommendations about some equipment such as cable and pipeline sizing.

Figure 2 - BEHYOND offshore hydrogen production facilities

The model results allowed the following general conclusions:

- As a function of wind farm rated power, net present value improved with increasing size from around 200MW to 1000MW,

- Hybrid systems, capable of exporting both hydrogen and electricity, optimised through the solver, saw the highest NPV,

- Hybrid systems that had identical electrolyser and wind farm capacity recorded lowest NPV, due to under-utilization of electrolysers and electrical equipment such as cabling and grid connection costs,

- Increases in distance from shore resulted in larger decreases in NPV for hybrid systems, with extra costs incurred for longer pipelines and especially export cables,

- Pipeline costs per kilometer were lower than the cable costs, so hydrogen only systems with no export cables had smaller cost increases and were the most financially viable option at distances greater than 130km,

- For hybrid systems, NPV increases with higher electrolyser capacity up to around 60% of total wind farm size.

Following the techno-economic model results, two configurations emerged as interesting concepts for further analysis: the ‘Decentralized Hydrogen only System’ and ‘Multi-centralized Hybrid System’. Both concepts are optimized and cost-effective solutions that can be configured and multiplied to meet the capacity needs in different applications and are easily configurable for different environments.

The ‘Decentralized Hydrogen only System’ is designed to be hosted directly on the wind turbine floating platforms. It eliminates the need for large electrical sub-stations and the extremely expensive HVDC cables, as the piping converges into a subsea manifold which will export hydrogen to land through a single pipe. Moreover, the required electrolyser capacities are conveniently like the current state-of-the-art thus easing phased investment.

On the other hand, the ‘Multi-centralized Hybrid System’ is placed on a dedicated bottom-fixed platform and, being able to produce and export both H2 and electricity, allows higher contractual flexibility and marketability. The use of multiple substations instead of just one not only enables phased investment, but also reduces the size of what could potentially be an oversized substation. Moreover, as a hybrid configuration, it balances the pros and cons of both centralized and de-centralized configurations.

At this stage the project shifted its focus to the engineering of both solutions. The global architectures were developed referring to the system boundaries, technical requirements, relevant standards, guidelines, external and internal interfaces. Additionally, all critical sub-systems of the hydrogen production module, together with their operational philosophies and O&M strategies, have been characterized following a deep analysis of the available technologies and direct engagement with different suppliers.

The technology selection for the identified main sub-systems is summarized here:

- Water Treatment Subsystem: Seawater Reverse Osmosis (SWRO) and Electro De-Ionization (EDI);

- Electrolyser Subsystem: Proton Exchange Membrane (PEM);

- Compressor Subsystem: Reciprocating Piston or Diaphragm;

Moreover, a novel control system and logic have been developed to accommodate different operating set-points of both the offshore wind farm and the electrolyser according to a combined understanding of external market signals and available wind resources. The proposed control and advisory system philosophy focuses not only on the total electrolyser load (or required hydrogen production), but also on the prioritization between electrolyser stacks in a coordinated manner that contributes to grid stability, and minimization of OPEX in terms of stack efficiency and lifetime.

The project then focused on the design of both the bottom-fixed and floating sub-structures and investigated the relative offshore operations & economic impacts. First, an estimation of the platforms footprint was based on the assessment of primary and auxiliary equipment (including fire system, winches and cranes), the evaluation of hydrogen safety requirements and the layout arrangement of equipment and interfaces. Secondly, the study estimated the platforms size and weight, designed the mooring system, sized cabling and piping, conducted dynamic analyses and assessed the associated costs.

As a result, from the project engineering phase, a novel marine operation and maintenance strategy of the hybrid energy system composed of the OWF and the offshore hydrogen production facility has been developed. Indeed, the assessment of viable installation, O&M and decommissioning strategies has allowed to better understand the logistical requirements while controlling economic impacts. This phase concluded with a set of recommendations for future extensions of relevant standards, guidelines and materials.

The last stage of the BEHYOND project aimed to contribute to the “bankability” of the proposed concepts by assessing the industrial readiness level across the supply chain and by implementing a risk management strategy to identify, quantify and mitigate the risks inherent to all the development stages. Indeed, the industrialization of a technology depends not only on the correct identification of the associated risks in terms of manageability, severity, and probability but also on the reliability of the risk mitigation measures to implement. Finally, to further improve the bankable hydrogen business model and allow access to the required capital investment, a commercialization roadmap was created to detail:

- the strategies to develop and commercialize the system,

- the targeted investors,

- risk dilution strategies,

- relevant financing mechanisms,

- the supply chain evolution expected,

- fundraising and attraction opportunities.

In conclusion, the BEHYOND project achieved advances in offshore hydrogen production beyond state of the art and highlighted the steps that need to be performed when moving forward for upcoming stages such as a proof of concept demonstrations project.