Onsite Demonstration and Prospects KEPCO’s Advanced Distribution Management System

The Korean government is pursuing energy transition policies to cope with “Global Carbon Neutrality by 2050” and to create future-oriented businesses that will create employment opportunities. To keep this issue in perspective, the ‘8th Basic Plan for Long-term Electricity Demand and Supply’ has been established, by which the renewable energy portion will amount to 20% by 2030 and will aim to reach 40% renewable generation by 2034.

Background

Since 2017, the DSO (Distribution System Operator) of “KEPCO (Korea Electric Power Corporation)” has put four years’ efforts to develop ADMS (Advanced Distribution Management System) for four main purposes: 1) Secured ability to supervise and control rapidly increasing renewable energy generation; 2) Increased hosting capacity by operating a flexible distribution network; 3) Reliability improvement with intelligent fault restoration; 4) Guaranteed sustainable management system through ‘In-house development’. (ref. CIGRE Electra 2021 Feb. Edition)

This article describes the first results obtained from the onsite demonstration of KEPCO’s ADMS carried out at its distribution network anticipating future application.

Overview of On-site Demonstration

The designed target performances and required functions of self-developed ADMS (Figure 1), have been evaluated through the on-site demonstration carried out systematically at real distribution network. The main checklists for validation are: 1) Operating stability implies the ability to overcome various faults taking place during operation; 2) Consistency of network analysis with actual the on-site situation describes that the actual distribution network power flow can be calculated despite the errors or the lack of measuring points; 3) Suitability of the provided solution accounts for figuring out the system inconveniences such as overload, overvoltage, and faults.

The first demonstration was carried out over a 23 day period beginning July 6, 2021 at Chung-buk branch. This field test site was selected because of its diverse power facilities already under operation: 11 distribution substations (154 kV), 131 distribution lines (22.9 kV), and 1,890 breakers and switchgears. In addition, 441 DERs (Distributed Energy Resources: 66 MW of Installed capacity, mainly PV) have been also connected.

Figure 1 - ADMS control room for on-site demonstration at Chung-buk branch, KEPCO

Results summary

Operating stability

Requirements

For a long time, KEPCO has employed small, distributed servers for DAS (Distribution Automation System) to manage local distribution networks operated by branch units. Nowadays, an investigation project has been launched to replace current server systems with an integrated large-scale server used for ADMS, which will enable HQ (headquarters) to manage the wide area distributed network. By focusing on HQ management, it was found to reduce system construction and management costs and increase operation efficiency. Should any server failures occur, the operational capability of wide area distributed network under control of HQ would be at risk. The new server should be designed to secure stability, and ensuring any unexpected malfunctions. In addition, high-speed data processing capability is required for the various users accessing to the operation data in real-time for multipurpose works such as distribution planning, design, operation, and technical review.

Achievements

During our demonstration, various difficult situations were tested such as power interruption, communication failure and hardware damage. Intentionally simulated failures were put into one or two clusters and the result shows that no interruption took place for 529 hours while the operating system was ascribed to the redundant triple clusters consisting of our integrated large-scale server.

In 2016, multiple failures happened at three substations and 60 distribution lines at KEPCO distribution system by a typhoon. A similar situation was tested in our simulation so that the large high speed data processing server could be verified. In this work, 5412 fault alarms caused by the malfunction of power apparatus or other accidents are transferred to 492 FRTU; on-site situations were correctly displayed on the server monitor within 10 seconds, our target time.

During the trial test period, it was proven that hundreds of operations, carried out at the distribution network level, were successful in many aspects such as new line constructions, line works and line faults. The average load rate of our server was 6.84% for the main unit, 6.11% for the middleware, 11.67% for FEP, and 8.78% for DB server; these results imply that the operation scale would be wide enough to be expanded to HQ level.

Benefits

Throughout the demonstration, our server system proved itself for HQ level application. As a result, 190 distributed server systems (currently used for DAS) could be replaced by 15 integrated large-scale server systems employed to ADMS. In this way, KEPCO projects to save approximately $60 million for the new system construction and maintenance over the next 20 years.

Consistency of network analysis with on-site actual situation

Requirements

DSE (Distribution State Estimation) and DGE (DER Generation Estimation) are the main goals of distribution network analysis.

The purpose of DSE is to calculate accurately two reference data such as the section load and the line voltages. The former is used for load transfer, line reconfiguration and DER connection. The other is applied to calculate the set value by which the related specified range by the regulation could be maintained. However, they are difficult to calculate as the number of measuring points at distribution network is low and measured values can often incude considerable errors. Anyhow, their accuracy should be absolutely respected.

DGE is carried out to estimate the electricity generation of unmeasured DERs or generation rate by use of the electricity generation of measured DERs. According to the Korean Grid Codes, 100kW of DER generation is the criteria to submit compulsorily the generation data to the distribution system operator. DERs less than this criterion, there is no duty to report so that they are classified as unmeasured electricity generation.

Achievements

Of the 131 distribution lines under management of Chung-buk branch, DSE and DGE have been carried out every 15 minutes for 99 public lines. Two cases are considered to obtain reference measurement value used for DSE, which depends on the position along each line of the concerned network: at the head and between middle and tail. One line meter (error 0.1%) is installed for the former and 5~10 switchgears (CT error 1%, PT error 3~10%) installed for the latter. Since the error of PT is not negligible, accurate estimation of voltage is so highly demanded as to limit the margin of error between maximum 1.76% and minimum 0.02%; these results imply that our target average of 2% is well accomplished.

In Korea, the national scale installation of smart meters (error 0.1%~0.5%) has been underway since 2010 and will be continued through 2025; many already under operation at the test site with concerned 99 lines. At each line, 3~5 points (head, middle, tail) are selected for the data acquisition of measured voltages by use of previously installed smart meters. All the voltages obtained from these 99 lines have been converted (220V to 13.2kV) for the comparison with the estimates used in the database.

Among the 441 PVs with total installed capacity of 66MW, only 8 power generation customers have reported reliable real-time electricity generation data through RTUs (Remote Terminal Units). Thus, generation rate has been calculated based on every 15 minutes’ average electricity generation from these 8 PVs. Afterwards, the total electricity generation calculation from the remaining 433 PVs was done by multiplying the generation rate to their installed capacity. In this way, the estimation error is disclosed between 5% and 13%.

Benefits

The real time DSE has been proved to be considerably accurate. This implies that KEPCO would be permitted to figure out the section load and voltage accurately in real time by use of the current surveillance systems without additional high precision sensor installation. Accordingly, the groundwork has been accomplished; the reliability of distribution system and hosting capacity of DER are improved through our DES with minimal current measuring system reinforcement .

The DGE has been evaluated to be inaccurate due to the low number of measuring points. Thus, it is necessary to keep the margin of error relatively high (within 2%) by increasing the number of measuring points with the generation rate correction by use of smart meter. In 2020, the total number of DER connected to KEPCO distribution network is 91,830 with 15,497MW of installed capacity. If the error is guaranteed within the margin, it would be sufficient to measure only 10% among all DERs since the electricity generation of the remaining 90% unmeasured DERs could be estimated without causing commercial inconveniences. In this way, hundreds of millions of dollars required for the installation and management of the RTUs may be saved.

Suitability of the provided solution

Requirements

Unlike transmission networks, distribution network reconfiguration takes place every day caused by diverse operations: grid connection, disconnection, or expansion due to the modification or elimination of load and generators. Therefore, distribution system operators should investigate technical pros and cons caused by the determined network reconfiguration while maintaining reliability and efficiency and line worker safety as well. All relevant solutions should be provided to make correct decisions for line overload, load transfer, voltage regulation and protection coordination.

Achievements

KEPCO has self-developed ‘Network analysis program on demand’ by which an on-site engineer can efficiently investigate operation pros and cons. During the demonstration period, 14 reconfigurations at distribution network level were tested to understand their ripple effects by use of self-developed program.

Once the connection with new load or DER asks for access, the hosting capacity of the system (substation, transformer, distribution line) is closely examined as to whether the power demand exceeds its limit or not, including the load transfer method for line works. In addition, line voltage is also checked to remain within specified range followed by the confirmation of the corrected set value to be applied to voltage controller such as OLTC and SVR.

DPF (Distribution Power Flow) is also calculated by the self-developed program; however, its accuracy has to be verified by our pilot operation. For this purpose, 99 lines under control of Chung-buk branch are put into calculating DFP using three tools: the self-developed program, ‘EPRI OpenDSS’ and ‘CymDist’. After that, their results are carefully compared with each other and the calculation difference is confirmed to be less than 0.1V @ 13,200V (phase to ground voltage of the 22kV distribution line).

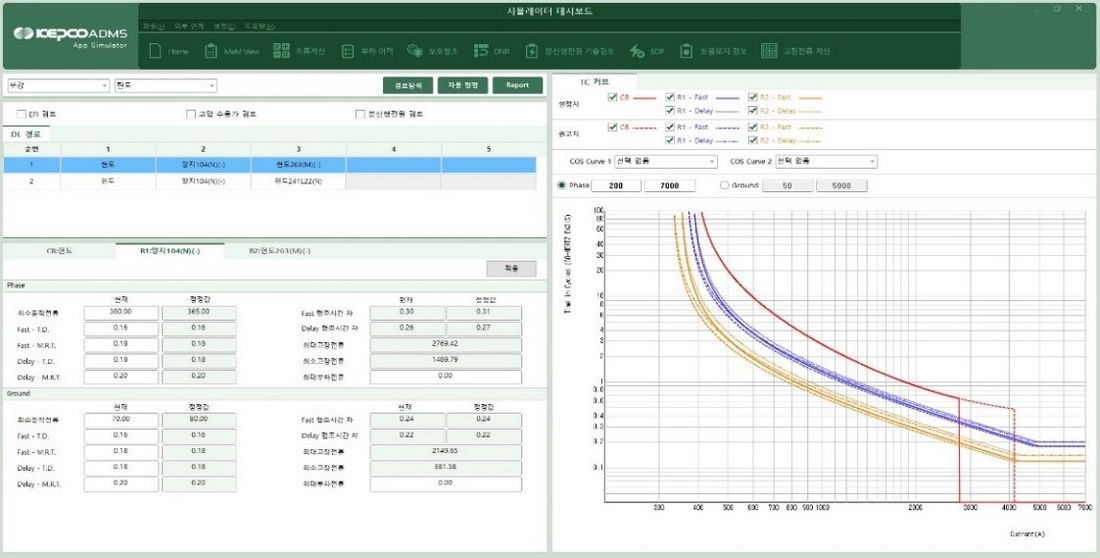

Examination of protection coordination is strictly required for the following cases: the reconfiguration at distribution line, installation or position change of protection device, and connection of new load or DER. When the re-closure is newly installed, its coordination with the circuit breaker is carefully examined. Considering the characteristics of the KEPCO distribution network, various faults at the load side are assumed, choosing two fault impedances (0 & 30 Ohms) respectively. For each case, fault current can be precisely calculated by our self-developed program deducing ‘Time-Current Curve’ by which required coordination time between circuit breaker and re-closure can be checked. The fault current calculation difference is less than 50A @ 8.2kA (maximum fault current directly under the substation bus) when our results are compared with those obtained using EPRI OpenDSS and CymDist.

Figure 2 - Protection coordination on the ‘On-demand network analysis program for ADMS’

Benefits

Our experiences, calculating power capacity, voltage, and protection coordination bring about the results with negligible differences when compared with those by other network analysis package programs. Thus, it could be approved that KPECO’s self-developed program provides relevant technical solutions conveniently when any reconfigurations are necessary at distribution network.

Prospects

Step-by-step deployment of KEPCO’s ADMS will be applied to 15 HQs nationwide by 2024. ADMS could improve engineering abilities to deal with the unexpected faults and to figure out the on-site situation occurring at the distribution network. By doing so, relevant, and proper operation and measures will be established quickly and appropriately. Besides, the hosting capacity of DERs can be increased by maximizing distribution network efficiency..

Futuristic development and on-site applications will continue, which is essential to upgrade the core competencies of ADMS. In addition, KEPCO will support the integration of renewable energy generation into national power grid based on our proven reliable achievements of ADMS activating practical cooperation with SCADA and EMS.

Acknowledgements

For this article, valuable contribution has been made by the technical staffs of HQ, Chung-buk branch, KEPRI of KEPCO, and Prof. Emeritus J.Y. KOO of Hanyang University. The author greatly appreciates their support and wishes to express his sincerest gratitude.

References

- KEPCO Electric Power Research Institute, “Performance test results of KEPCO ADMS, October 2020

- KEPCO Distribution Planning Office, “Onsite Demonstration plan for KEPCO ADMS on the distribution network in Chung-buk Branch”, May 2021

- KEPCO Distribution Planning Office, “Onsite Demonstration results for KEPCO ADMS on the distribution network in Chung-buk Branch”, August 2021

Thumbnail credit: zero take on Unsplash