Balancing competing requirements when specifying bird protective covers

Electrical utility engineers are often required to write standards for equipment to be used on transmission and distribution networks. The importance of balancing the “ideal” technical requirements with the practicality of meeting those requirements and the cost is well known. For example, including a certain type test may lead to a more reliable product, but that test may be difficult or expensive to perform and so the costs of requiring such a test may outweigh the benefits. An important source of information to assist with compiling a well-balanced standard is firsthand field experience with the product in question; this has been shown to alleviate the need for certain tests and to identify the need for others that would not ordinarily have been thought of.

by Andreas Beutel, Bruce McLaren, Mohamed Khan, Rudi Kruger (Eskom Holdings SOC Ltd)

Introduction

This article explores these concepts by outlining the process used in the compilation of a new standard for protective covers used on overhead medium voltage (11-33 kV) power lines in South Africa for reducing the risk of bird electrocutions and bird-related power interruptions. Standards, other available literature and field experience are drawn on, with the purpose of providing a case study that could be used for compiling the standard of similar or different equipment.

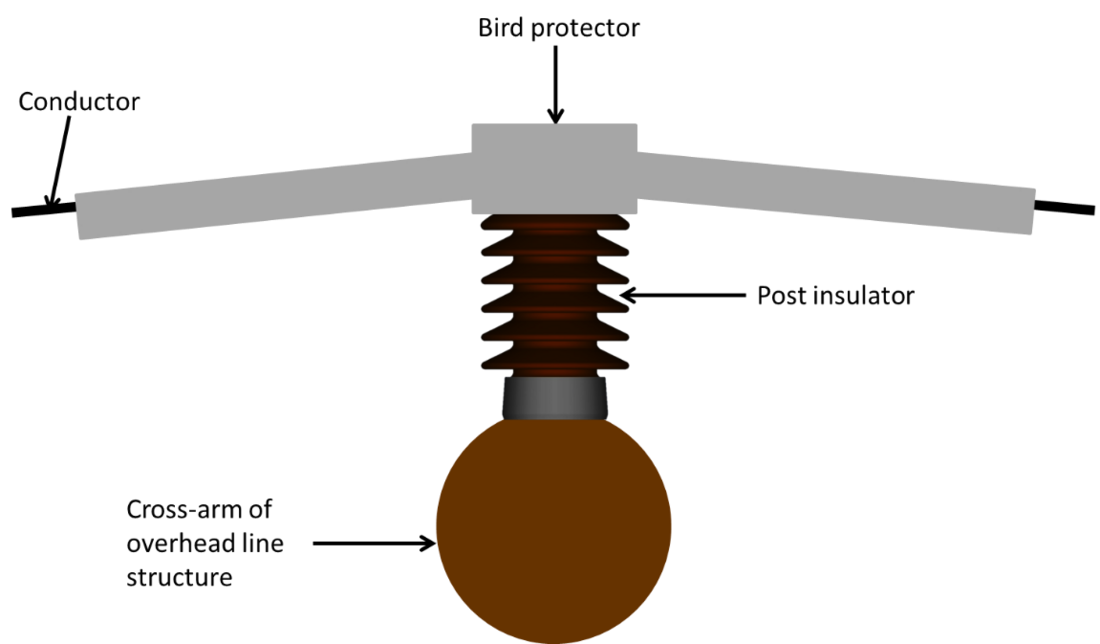

Bird protectors

This equipment is placed over post insulators, installed on medium voltage (MV) overhead lines, to prevent birds from make contact with live electrical parts, and in so doing to reduce the risk of bird electrocution and associated electrical faults. The line structures are typically made of wood, but the equipment may also be used on structures made of other materials, e.g. steel or concrete. These products do not necessarily provide insulation at the full network voltage, because they only need to provide protection against momentary contact (a similar principle to covered conductor [1] ). Two different products illustrating this principle are shown in Figure 1.

Bird protectors have been used on South African MV lines for many years and have in general proved to be an effective way of reducing bird mortality. However, field visits undertaken as part of a process of continuous improvement showed the need for reviewing the current standards for both the product itself and for its application. In any case, it is prudent to review most standards periodically to take into account new information such as technology advances and changes in industry standards.

Figure 1 - From left to right: Bird protector principle, product installed on vertical post insulator and on horizontal post insulators

Process followed to revise the existing standard

The following inputs should be considered when revising a standard such as this:

- The current standard.

- Applicable local and international standards.

- Field experience.

- Quality history.

- Published experiences from other utilities.

- Application of the equipment – in this case determining the ways in which birds can get electrocuted on MV line structures .

In the case of this product, IEEE Standard 1656 (IEEE Guide for Testing the Electrical, Mechanical, and Durability Performance of Wildlife Protective Devices on Overhead Power Distribution Systems Rated up to 38 kV) [3] is directly relevant. However, it should be noted that the IEEE document is intended as a guide only and one should not be requiring compliance with the entire document without first performing due diligence. This is especially true in the South African context because local manufacturers may not be familiar or compliant with North American standards, with the result that additional requirements specific to one utility or country may be required. This should be avoided as far as possible due to the additional cost implication. As a result, compliance to South African standards adopted from the IEC was required as far as possible because these would already be known in the local industry. However, there is no known South African or IEC standard that specifically deals with this equipment, and IEEE 1656 provides excellent reference material. Also, one needs a good engineering reason for discarding certain clauses and replacing others. For example, the flammability tests recommended in IEEE 1656 are from an IEC standard that has been adopted in South Africa, while radio interference voltage testing on non-electrical components is not considered necessary at MV (as opposed to transmission voltages) – but may become relevant in future as cellular communication becomes more widespread.

Field experiences

This involved inspecting bird protectors that had been installed in the field some time ago (well over ten years prior to the inspection in some cases). The purpose was to determine whether the mechanical and electrical performance was satisfactory and what the impact of age and different protector, insulator and structure designs is. Areas with, respectively, high lightning density and high coastal pollution level were chosen. Where possible, the inspection included removal of products and close-up examination, as well as inspection of the hardware underneath the protectors. The result is a detailed understanding of the impact of aspects such as different insulator materials (e.g. porcelain or silicone rubber) and conductor ties, accumulation of dust, presence of electrical tracking and erosion, effects of flashover, the durability of different fastening mechanisms and ease of installation and of performing maintenance inspections.

Some findings did not require explicit addressing in the new standard, examples are shown in Figure 2. These are surface marking due to flashover, dust accumulated due to the lack of rain washing and mild but inconsequential electrical tracking.

Figure 2 a & b- Examples of field inspection results not considered a problem – internal flashover (a), dust accumulation under protector (b) and electrical tracking (c)

Figure 2 c - Examples of field inspection results not considered a problem – internal flashover (a), dust accumulation under protector (b) and electrical tracking (c)

Other findings directly influenced the standard by, for example, showing the need to include the different shapes of porcelain and silicone rubber insulator heads and to carefully consider the fastening mechanism. An example of the latter is the use of metal wires instead of the supplier-specified fasteners, this defeats the purpose of installing a protector to an extent because it shortens the path for phase potential to get onto the outside surface of the protector. Also, off-the-shelf cable ties were used in places; this is also unsatisfactory because these are not formally specified items and may therefore degrade in a short time due to UV exposure. The reason why wires or cable ties were used is not known, but the practice highlights the need to ensure that the fastening mechanism is practical to install and durable.

Another aspect identified is that this equipment makes it more difficult to inspect pole-top hardware during routine maintenance inspections, because it covers much of the hardware such as the conductor and conductor ties. This is alleviated somewhat by an opening underneath, which is required to reduce the risk of conductors burning off due to repeated flashover at the same point. However, the shadow of the cover over the hardware and the distance of observation from ground level still makes this task a challenge.

Experiences from other utilities

The results of a Hungarian study on similar products [4,5] found conductor damage under bird protectors. The most similar damage found in South Africa is shown in Figure 3. This shows no clear and obvious signs of arcing or melting of metal, the small signs of melting are a normal sign of flashover. There are also some signs of abrasion, but this is again not considered severe enough to be of concern. Possible conductor and tie corrosion due to the moist environment was found underneath one bird protector, but it has not been possible to confirm this. Considering the lack of any widespread or confirmed damage similar to the Hungarian case, it was decided that those findings do not apply to the South African situation. A reason for the difference may be the fact that Hungarian cross-arms appear to be conductive and directly earthed, whereas the pole-top hardware is not usually directly earthed in South Africa.

Figure 3 - Conductor tie damage underneath a bird protector

Experiences in the USA have been documented in . This document provides another useful source of information on the application of bird protectors.

Summary

The exercise described in this paper shows that when compiling or reviewing an equipment standard it is important to gather as much input information as possible, including local, international and foreign standards, literature published on application of the product and firsthand field experience with the same or similar product (in addition to information gathered as part of any commercial processes). The gathered information should then be critically analyzed to determine what is relevant and practical to the context in which the equipment will be used and what is too costly to include or should be discarded for other reasons. Simplified examples are shown in Table 1. Performing such due diligence is time well spent because it can save a utility much expense later.

| Performance criterion | Possible references | Advantages of including | Disadvantages of including |

| Wind resistance retention test | IEEE Std 1656 [3] | Provides confidence that the product will remain in place |

|

Ultraviolet (UV) aging test | IEEE Std 1656 [3] IEC 62217 [7] | Provides confidence that the product will survive in the field | The test specified in [1] is not widely known outside of North America, whereas the test specified in [5] is not intended for this equipment |

| Material fingerprinting test | CIGRE TB 595 [8] | Provides a history of the material used for the product for engineering investigations | Adds cost & may not be considered essential |

| Wet system frequency withstand test | IEEE Std 1656 [3] | Establishes the product’s electrical characteristics | Option 1 may be too complicated to perform safely |

| Mechanical pull test on installed product | - | Provides additional confidence that the product will remain in place | Standardization is difficult because there is no known industry standard |

References

- T. A. Short, “Electric power distribution handbook”, CRC Press LLC, Ed 2, 2014, Section 2.2.

- A. Beutel, B. McLaren, C. Hoogstad, R. Kruger, H. Geldenhuys, “Using citizen science to address bird electrocutions on overhead distribution networks”, CIGRE Electra, No. 312, Oct 2020, pp. 50-53: https://electra.cigre.org/312-october-2020/technology-e2e/using-citizen-science-to-address-bird-electrocutions-on-overhead-distribution-networks.html

- IEEE Guide for Testing the Electrical, Mechanical, and Durability Performance of Wildlife Protective Devices on Overhead Power Distribution Systems Rated up to 38 kV, IEEE Std 1656™2010, 2011.

- G. Göcsei, B. Németh, R. Cselkó, I. Berta, “Bird protector-related issues on medium voltage overhead networks” Proceedings of the 11th International Conference on Live Maintenance (ICOUM 2014), Budapest, Hungary, May 2014.

- G. Göcsei, B. Németh, R. Cselkó, I. Berta, B. Torda, “Bird protection on medium voltage power lines”, Proceedings of the 23rd International Conference on Electricity Distribution, Paper 1288, Lyon, France, Jun 2015.

- Avian Power Line Interaction Committee (APLIC), “Suggested practices for avian protection on power lines: the state of the art in 2006”.

- IEC 62217, “Polymeric HV insulators for indoor and outdoor use – General definitions, test methods and acceptance criteria”.

- CIGRE Technical Brochure 595, “Fingerprinting of Polymeric Insulating Materials for outdoor use”, Oct 2014. : https://e-cigre.org/publication/595-fingerprinting-of-polymeric-insulating-materials-for-outdoor-use

Thumbnail credit: Photo by Ridham Nagralawala on Unsplash