Guideline on Testing of Turbo and Hydro Generators

The maintenance, inspection and testing of large generators remains one of the most significant costs of asset ownership for electricity generation companies worldwide. Competitive reforms in electricity utility ownership and change in operational practices have imposed significant cost pressures. As a result, in many countries these processes forced utilities to reduce maintenance and inspection frequency and accept greater operating risk, albeit through managed risk assessment and mitigation programs. There is both factual and anecdotal evidence that in some instances the risk envelope is being stretched quite significantly compared to previous practice.

Members

Convenor

(CA)

M. ŠAŠIĆ

H. SEDDING (CA), D. JOVANOVIĆ (RS), H. SHIMADA (JP), J. WEIDNER (GE), P. WIEHE (AU), T. HILDINGER (BR), M. BRČIĆ (HR), D. TARRANT (ZA)

Introduction

In August 2009, Study Committee A1-Electric Machines has published Technical Brochure 386 ‘Generator Maintenance, Inspection and Test Programs’ to provide recommendations regarding maintenance, inspection and testing of turbo generators in power plants. However, the necessity of having a new document in order to provide guidance to plant personnel on test procedures and practices to ensure equipment integrity, including hydro generators was felt and this new TB includes survey results for both turbo and hydro generators.

Scope/Methodology

Following CIGRE’s tradition the data were collected by means of a survey made through a questionnaire. The objective of this study was to survey actual and recommended practice concerning the testing of turbo and hydro generators. The survey was limited to turbo generators with ratings > 250 MVA and hydro generators > 30 MVA. A questionnaire was created that contained more than 120 questions distributed over 16 categories. The questions were related to the following aspects of the generator testing:

- Stator winding slot content

- Stator winding end windings

- Stator core

- Stator cooling water system

- Rotor windings

- Additional reported tests

For the aspect of the stator winding slot content, questions on the application of wedge testing, the winding resistance and impedance measurement were covered. In addition, a number of questions in the survey were asked on the seven topics such as the measurement of the insulation resistance (IR), determination of the polarization index (PI), Dielectric Loss Analysis (DLA), Dielectric Dissipation Factor (DDF) respective tan delta measurement, Partial Discharge (PD) measurement and the high voltage withstand test either with AC, DC voltage in the normal 50-60Hz range or with Very Low Frequency (VLF).

In case of the stator end winding the questionnaire focused on industry practices related to Capacitance Mapping and Modal Response Testing. Concerning the stator core, the questions were related to the method used to assess the condition of the core interlaminar insulation, such as high flux testing and EL CID testing. The tightness test of the water-cooling system was addressed. Concerning the rotor, dielectric tests such as IR, PI, high voltage withstand test (either with AC, DC or VLF) and Repetitive Surge Oscillograph (RSO) tests were covered, as well as tests that assess mechanical aspects, like Non-Destructive Testing (NDT) on Coil Retaining Rings (CRR’s).

The responses have been correlated and analysed to create this TB. The responses were segregated into two categories: users and manufacturers/consultants/labs. These categories are reported separately in chapter appendices and combined in the analysis of the relevant testing practices.

The survey obtained 37 responses on utility practice from 13 countries. The responses from utilities cover test practices from more than 2000 utility generators.

Structure and Content of the Technical Brochure

This TB is divided into five Section, as follows:

- Introduction

- Responses

- Turbo Generator Testing

- Hydro Generator Testing

- Conclusion

Three Appendices are attached providing Definitions, References and Table with all responses.

In the second Section, two tables are shown indicating Country and type of the generators used by respondents. The first table provides a summary for 14 manufacturers, labs and consultants, and the second one for 23 utilities that answered the questionnaire.

In the third Section, analysis of 19 responses on 19 tests performed on Turbo generators is provided. For each test a brief introduction explaining the test details, references and if appropriate, acceptance criteria are provided. In the questionnaire, multiple questions were asked for each test (4-9 questions per test) and the responses on each question are shown in graphical form.

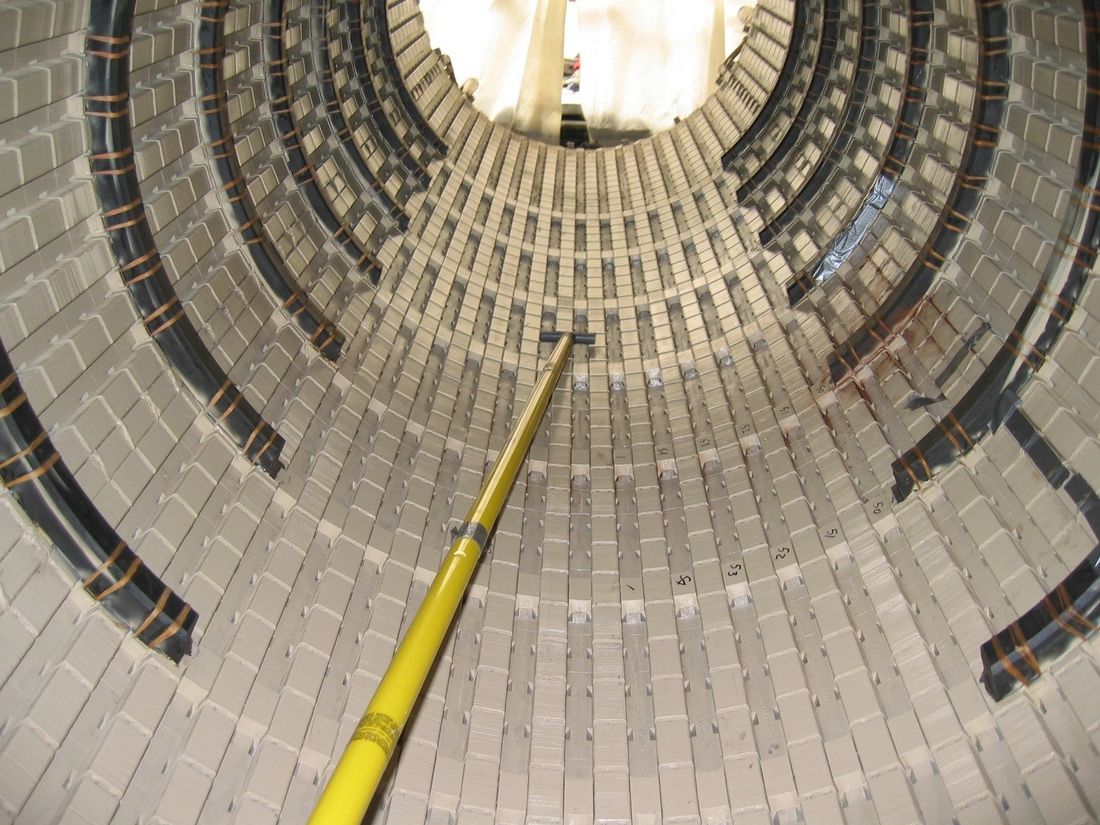

Figure 1 - Turbo generator testing in progress

In Section four, in similar manner, 24 responses on 18 tests performed on Hydro generators are shown.

Figure 2 - Hydro generator testing in progress

Conclusion

The survey has provided a basis for comparison by utility engineers of maintenance practices across a limited range of countries. The responses reported in the appendices provide a library of test recommendations and actual practices that could be considered if new or modified practices are being contemplated. To some degree, operational problems (and test practices resulting from them) can be correlated to a generator manufacturer or certain generator model. Consequently, some OEM recommendations will affect type and frequency of the tests performed. This aspect was outside the scope of the survey.

The aims of the study have largely been met, although the reasons for the differences in approach highlighted in the various areas of maintenance practice surveyed were not adequately explained by the data received. The most significant conclusion is that there is a considerable diversity in approach and practice in use internationally. It has proven unrealistic to anticipate that a study such as this can identify best or preferred practice in any particular area of generator testing.

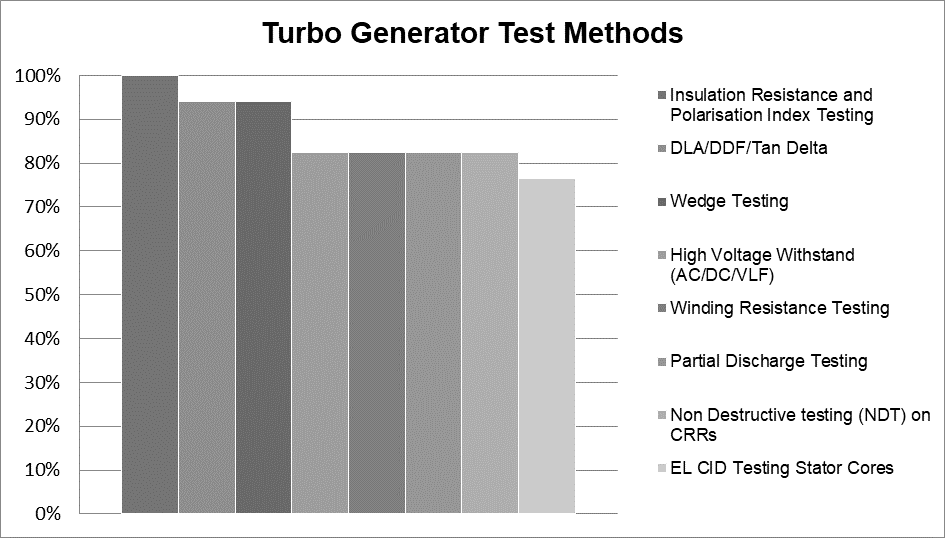

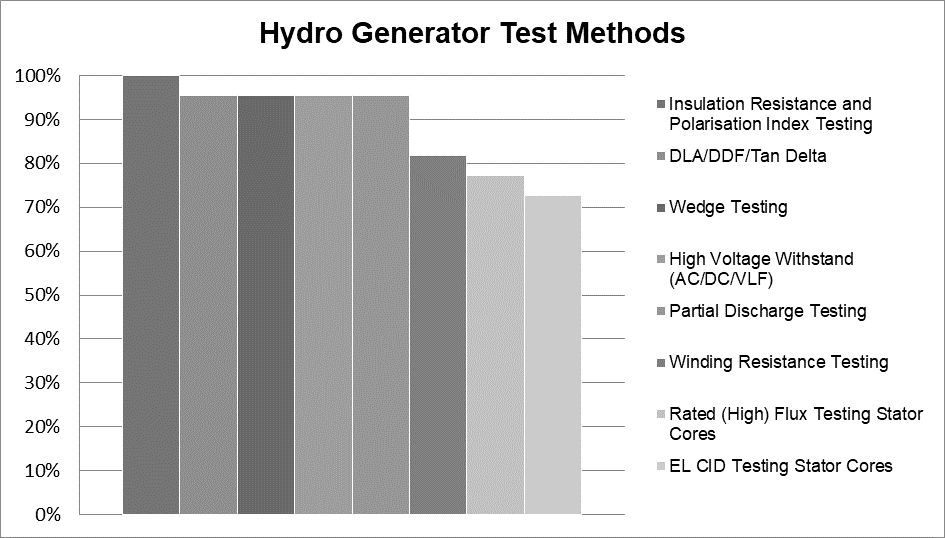

The most frequent test methods used on turbo generators are shown in Figure 3 and Figure 4 indicates most frequent test methods used on hydro generators. The percentages shown in tables are based on number of positive answers in all submitted questionnaires, for example all respondents indicated that they perform Insulation Resistance and Polarisation Index Testing.

Figure 3 - Most frequent test methods for turbo generators

Figure 4 - Most frequent test methods for hydro generators