Dielectric characterisation of polymeric materials for outdoor use

Aim of the work was to explore methods for dielectric characterisation of polymeric insulating materials. In the first phase of the work, a literature review was performed and different available dielectric diagnostic methods in the time and frequency domain were reviewed. Especially the application of the methods was of main interest. In the second phase of the work the contact and contact-free methods were investigated in detail. Test setups and related test specifications have been developed within the contributing members and participants of the Round Robin Tests (RRTs). In the third phase of the project work RRTs were performed in order to study the feasibility of different test methods using different commercially available test equipments for different kinds of insulation materials.

Convenor

(DE)

J.M. SEIFERT

Secretary

(DE)

S. KORNHUBER

C. BÄR (CH), O. BENDONG (CN), T. CARREIRA (CA), S. CHAMBERS (UK), Y. DENG (CN), T. DENG (CN), T. GOVENDER (ZA), S. GUBANSKI (SE), T. HAYASHI (JP), J. HEGGE (DE), A. HERGERT (DE), H. HOMA (JP), B. KOMANSCHECK (DE), T. KONDOU (JP), B. KRUSKA (DE), J. LACHMANN (CZ), J. LAMBRECHT (DE), F. LEHRETZ (DE), S. LI (CN), X. LIANG (CN), N. MAHATO (ZA), A. MUSHTAQ (SA), M. NAGAO (JP), D. OLIVER (CA), D. RAMALHO DE MELLO (BR), S. ROWLAND (UK), G. SALVO (AR), F. SCHMUCK (CH), M. STÜFER (DE), F. VIRLOGEUX (FR), W. VOSLOO (ZA), J. WANG (CN), Y. WANG (CN), N. WEST (ZA), C. WU (CN), X. XIANGDONG (SE), M. YAMARKIN (RU), Z. YAN (CN), Y. ZHANG (CN), J. ZHOU (CN), Y. ZHOU (CN)

The focus of this work was on materials, not on apparatus or on insulation systems. The general Term of Reference (TOR) is only defining the scope to new materials. However, it was also possible to study ageing effects such as humidity and acid impact for some selected materials.

The following conclusions are derived from the work and recommendations are given:

- Frequency Domain Methods (FDM) are recommended. Time Domain Methods (TDM) were not investigated

- Frequency Domain Methods (FDM) show good applicability in the frequency range of 0.1 mHz – 10 kHz (“Very Low Frequency (VLF) and “Low Frequency (LF) range)

- Both, contact and contact-free methods are suitable and reasonable

- A test specification was defined and succesfully applied

- The definition of a drying process is important and was specified

- Test equipment and electrode arrangements including shielding can be recommended

- 3 Round Robin Tests (RRTs) were performed (additionally one explorative RRT)

- Test results can be compared in a qualitative way

- The effect of humidity is clearly detectable (mositure affects mainly the volume properties)

- The effect of acid is not detectable (acid affects mainly the surface properties)

Hypothesis: Method is suitable in order to detect volume related dielectric effects (e.g. by moisture). In this study, the method was only applied to materials. Future studies should consider more complex arrangements including material interfaces and insulation systems

The achieved results exceed the expectations by far, since additionally the methods were not only applied to new materials but also to artificially aged materials. This shows the enormous potential of FDM diagnosis to detect volume related ageing processes in insulating materials (polymer, composite and interfaces of composite materials) and complete insulation systems (cable accessories, transformers, insulators, bushings etc.). Further investigations for the application to complex insulations and insulation systems are recommended.

Dielectric spectroscopy

Dielectric properties of materials and insulation systems depend on many factors including the frequency of an applied stimulus (voltage or current), the temperature, as well as their chemical composition and structure. Within electric power engineering, the dielectric properties, e.g. permittivity and dissipation factor are parameters that play a key role in design considerations and the frequency of interest. For these application it is generally limited to the power frequency for which the equipment is designed. However, this approach is sometimes insufficient and there is a need for characterisation of these parameters over a broader range of frequencies in order to properly qualify materials for complex insulation systems (HVDC, converter technology, bushings, cables etc.).

As soon as a material is exposed to an electric field, movement of electric charges occurs which results in the creation of dipoles and a state of dielectric polarization. This process, can externally be observed as the macroscopic polarisation, P , which represents the sum of individually polarized species per unit volume of the material.

The contributions to the macroscopic polarisation P of a dielectric are classified as follows:

- Electronic polarisation,

- Ionic (or atomic/molecular) polarisation,

- Dipolar (or orientation) polarisation,

- Interfacial polarisation,

- Space charge polarisation of trapped and/or hopping charge carriers.

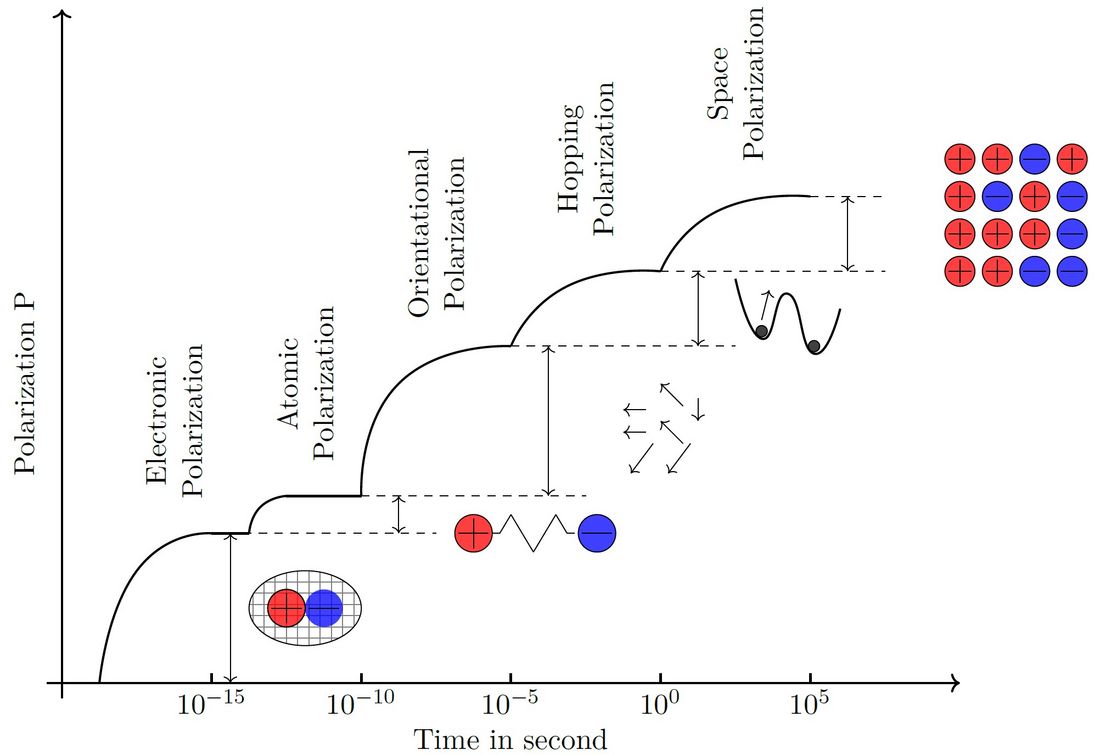

Each of these processes responds to an applied field over different timescales. Thus, the time dependency of the polarisation P may be observed over a very wide time span within a material sample, starting from instantaneous responses to responses lasting for tens or hundreds of hours. A schematic representation of this process is provided in Figure 1.

Figure 1 - Physical polarisation processes

Under the exposure to an electric field, electric conduction also occurs. The dielectric response of a material is the quantification of both the polarisation and the conduction effects, and its determination can either be performed in time domain (by measurements of polarisation and depolarisation current (PDC)), or in the frequency domain (by measurements of the complex permittivity by using the Frequency Domain Spectroscopy (FDM)). FDM methods was selected for the Roudn Robin Tests (RRT).

Dielectric spectroscopy measurements in the frequency domain involve determining the current and its phase angle with respect to the applied alternating voltage. Based on this principle, the complex impedance of the tested material or insulation system is obtained by sweeping over desired frequency range, for which dependences of the relative permittivity (εr ) and the dissipation factor tanδ) are obtained.

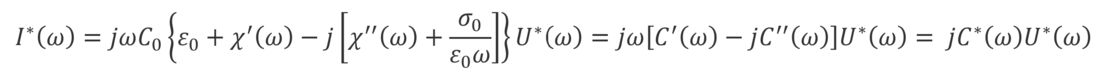

In many practical cases, the technique refers to slow polarization processes. Considering a single frequency component, ω, the resulting current can be expressed as:

where U*ω is the applied voltage , χ'ω and χ''ω are the real and the imaginary components of the complex susceptibility, χ*ω, incorporating all of polarization processes within the test object, while C'ω and C''ω are the real and imaginary components of the complex capacitance, C*ω . Applying this expression, the measured values of magnitude and phase for the response current can be used to calculate the complex permittivity. C0 (geometrical capacitance is determined by the dimensions of the test object). The significance of the term σ0ε0ω is the DC conductivity and contributes to the measurement of apparent dielectric losses. Therefore, distinguishing between conduction and polarisation losses in the insulation material requires additional data analysis.

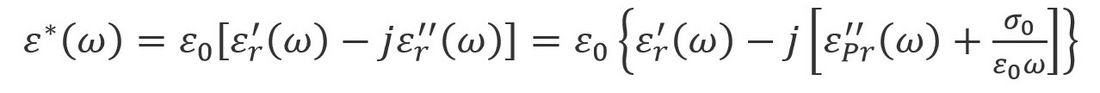

In the frequency domain, the dynamic dielectric properties are expressed in terms of complex relative permittivity, ε*(ω):

If the geometrical capacitance is known, the frequency dependent dissipation factor tanδω can be expressed as:

εr': real part of complex εr

εr'': imaginary part of complex εr

εPr'': imaginary part of complex εr solely including polarisation losses

Test method

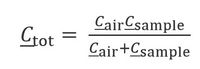

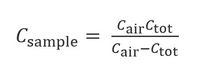

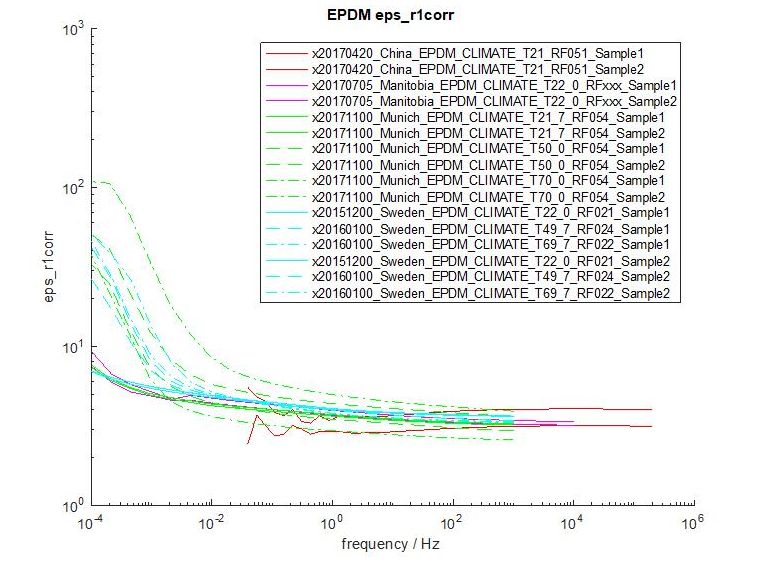

The “contact-free” method [1] was applied for the round robin tests. The idea of a “contact free” dielectric response measurement is to place a piece of a flat dielectric material on the bottom electrode without direct contact with the top electrode. As there is no pressure applied from top electrode, deformation of the sample can be neglected. Moreover, without any direct surface contact between sample and electrode, influence of the surface conductivity is limited. A partially filled test gap can be modeled by two series connected capacitors, resulting in a total capacitance as given by equation

where, Csample and Cair are the complex capacitances of the sample material and the air inside the electrode gap. From equation above, the sample capacitance can be calculated if the air gap and the total capacitances are known:

The air gap capacitance can be obtained from the air reference measurement, described in the next section, by correcting for the changed distance. Similar approaches were mentioned in [2]. In this paper we are however additionally using air as reference to calibrate the measurement instrument. A detailled test specification was developed including sensitivity analysis and recommendations in order to avoid distrubances and reduce scatter.

Figure 2 - Illustration of the contact-free testing system with FDM instrument

Results of Round Robin Test (RRT)

Three round robin tests were performed at 6 different laboratories. The materials shown in Table 1 were tested und the mentioned conditions. Additionally, some materials were investigated in new and aged condition (water immersion and acid storage).

Table 1 - Investigated materials and test conditions

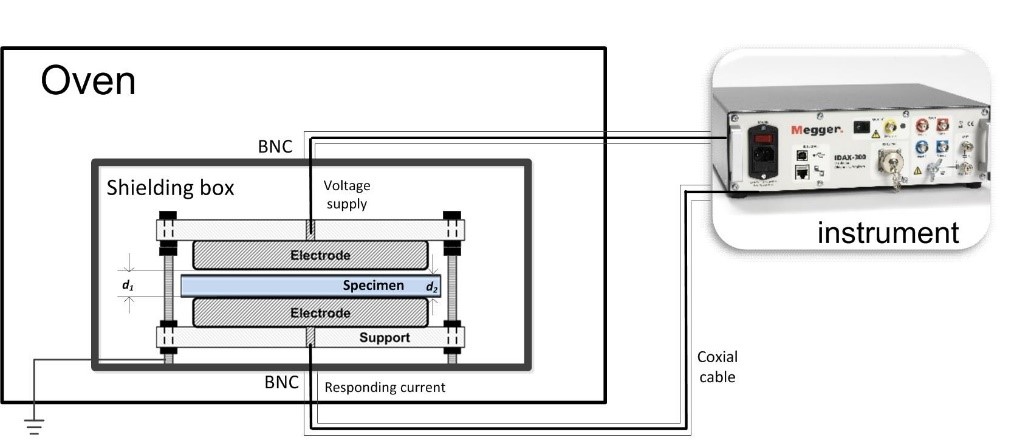

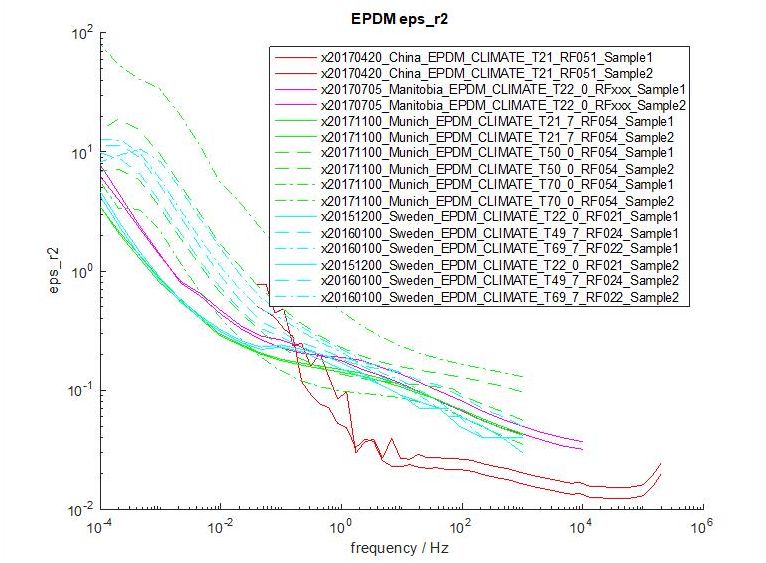

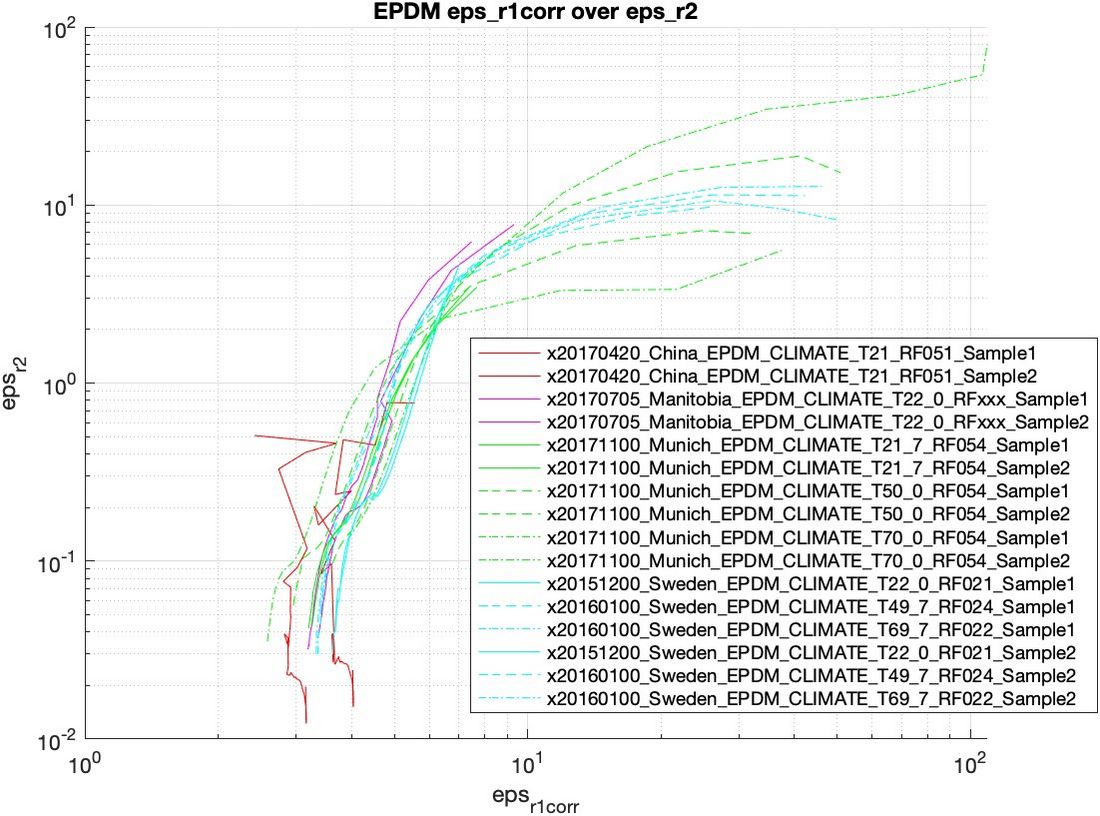

Typical test results (only one material example for EPDM) are shown in Figures 3, 4 and 5.

Figure 3 - Relative permittivity (real part) in dependence on test frequency

Figure 4 - Relative permittivity (imaginary part) in dependence on test frequency

Figure 5 - Cole plot (imaginary versus real part with frequency f as parameter)

Evaluation and Recommendations

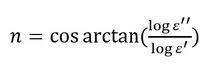

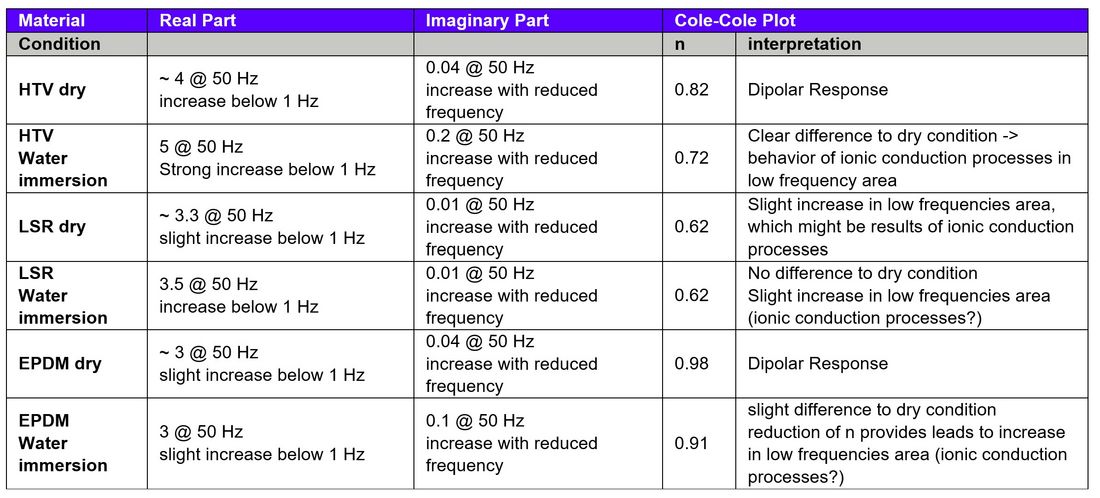

A detailled literature review was performed and the required theories for understanding dielectric phenomena were compiled. A theoretical model was derived in order to evaluate the experimental results. Both, contact and contact-free method were investigated and assessed as suitable and reasonable. Experimental work (round robin tests) were performed applying frequency domain methods (FDM) with the contact-free sample arrangement. The test results are summarised in Table 2. The evaluation and intepretation were done by means of the coefficient

Table 2 - Test results of contact-free FDM and interpretations

It is recommended to apply FDM for the detection of material change such as ageing and or deterioration effects [3]. FDM show good applicability in the frequency range of 0.1 mHz – 10 kHz (“VLF” and “LF” range) [4]. A test specification was defined and considered as useful including the important definition of the dyring process before testing. Test equipment (devices and setup) and the important electrode arrangements including shielding box are recommended in the test specifcation. Three round robin tests (RRT) were performed (additionally one explorative RRT). The RRT results can be well compared in a qualitative way. The effect of humidity is clearly detectable (mositure is affecting mainly the volume properties espcially at internal micorscopic interfaces between filler and matrix material). The effect of acid is not detctable (acid is affecting mainly the surface properties). The FDM is suitable to detect volume related dielectric effects (e.g. by moisture). In this study, the method was solely applied to material samples. Selected matrials frequently applied in HV outdoor insulation such as HTV and LSR silicones, EPDM, and epoxy resin with mineral fillers were investigated. Next studies should consider more complex arrangements including material interfaces and insulation systems. For this purpose a new WG is recommended with members / stakeholders for different insulation applications, for example, transformers, cables, bushings and HV apparatus. The achieved results exceed the expectations by far since additionally the methods were not solely applied to new materials but also to artificially aged composite materials. This shows the enormous potential of FDM diagnosis to detect volume related ageing processes in insulating materials (polymer, composite and interfaces of composite materials) and complete insulation systems (cable accessories, transformers, insulators, bushings etc.).

Conclusions

- 3 Round Robin Tests (RRT) were performed (additionally one explorative RRT) using FDM

- Test results can be compared in a qualitative way

- The effect of humidity is clearly detectable (mositure is affecting mainly the volume properties)

- The effect of acid is not detctable (acid is affecting mainly the surface properties)

- Hypothesis: Method is suitable in order to detect volume related dielectric effects (e.g. by moisture)

- [1] Xu, X.; Bengtsson, T.; Blennow, J. and Gubanski, S.: “Enhanced accuracy in dielectric response material characterization by air reference method,” IEEE Trans Dielectr. Electrical Insulation, 20(3) (2013) pp. 913-921.

- [2] IEC 62631-2-1: Dielectric and resistive properties of solid insulating materials – Part 2-1: Relative permittivity and dissipation factor – Technical frequencies (0,1 Hz to 10 MHz) – AC Methods, 2018.

- [3] Seifert, J. M.; Stietzel, U.; Kärner, H.C.: The Ageing of Composite Insulating Materials - New possibilities to detect and to classify ageing phenomena with dielectric diagnostic tools, in Proc. of the 1998 IEEE International Symposium on Electrical Insulation, Arlington, Virginia, USA, June 7-10, 1998, pp. 373-377

- [4] Jonscher, A.K.: Dielectric Relaxation in Solids. Chelsea Dielectric Press, 1st Edition, London, UK, 1983