Current interruption in SF6-free switchgear

The Technical Brochure of WG A3.41 deals with the technology, availability and application of SF6-free transmission and distribution switchgear. It focuses on the mainstream of upcoming SF6-free current interruption technologies, on the one hand based on interruption in natural-origin gases and their mixtures with fluoronitrile (C4-FN), fluoroketone (C5-FK), and on the other hand based on technical air-insulated vacuum circuit breakers. Despite the different physical characteristics of the SF6-free alternatives, minor modifications enable similar performance, application range and size as their SF6 equivalents, at present up to 170 kV. Products and (pilot) projects with SF6-free switchgear are reported in this Technical Brochure.

Members

Convenor

(NL)

R.P.P. SMEETS

Secretary

(NL)

A.G.A. LATHOUWERS

Document Editor

(NO)

N.S. STØA-AANENSEN

M. ARENS (BE), E. ATTAR (NO), T. BERTELOOT (FR), G. BLANCHET (NO), M. CLAESSENS (CH), N. DEMARTHE (BE), R. DOCHE (CA), J. DOUCHIN (FR), M. ECSERI (HU), N. GÖTTE (DE), C. GRÉGOIRE (FR), T. HEINZ (DE), T. INOUE (JP), H. ITO (JP), R. JAIN (US), S. JIA (CN), A. JEANMAIRE (FR), D. JOHNSON (US), H.E. JUNG (KO), H.-K. KIM (KO), A. LEE (HK), X. LI (CN), J. MANTILLA (CH), M. MARTÍN (ES), M. MURATOVIC (BA), N.M. NGUYEN (FR), J. OWENS (US), J.H. PARK (KO), M. PERRET (CH), D. PESCH (DE), P. PIETRZAK (CH), M. RAMESH (DE), J. ROSTRON (US), M. SATO (JP), D. SCHIFFBAUER (US), Z. SMITH (US), D. VALMACCO (BE), X. YAN (CN), B. WÖLKE (DE)

Introduction

All transmission and distribution (T&D) switchgear needs dedicated media for insulation and arc extinction. While at the distribution end of the voltage range solid materials and air fulfil the electric insulation function frequently, and switching is mostly performed with vacuum circuit breakers, sulphur hexafluoride (SF6) is dominating the transmission voltage ratings since the 1970s. SF6 gas has properties that combine insulation and switching capability up to the highest levels. During the past decades, however, it is recognised that SF6 is a major greenhouse gas, having a CO2 global warming potential (GWP) equivalent of 23 500 [1], which leads to growing environmental concern, materialised in a multitude of regulations regarding its use.

In the electrical power industry, SF6 is primarily used for the electrical insulation in T&D equipment, with the largest quantities used in high-voltage gas-insulated switchgear (GIS).

Alternatives to SF6 in switchgear must serve one of two functions:

- External electric insulation of vacuum interrupters. This approach is a long standing one applied in distribution and is penetrating (sub)transmission switchgear up to 170 kV at present. The insulation medium is mostly natural-origin gas with pressure depending on the voltage level.

- Switching and electric insulation with a pressurised gaseous medium. This is mostly a mixture of CO2 as a carrier gas, with an addition of O2 and (but not always) a synthetic fluorinated compound with a GWP much lower than SF6. In this case, the gas mixture has an active role in current interruption. At the time of writing this document, this principle can be found in products in a voltage range of 10 –170 kV and is applied in all switchgear: circuit breakers, load break-, (high-speed) earthing- and disconnecting switches.

Technology

Chapters 1–5 of the Technical Brochure highlight the technical/physical challenges and how they are met in SF6-free switchgear.

In chapter 1, various gases are introduced, along with their thermodynamic properties that are essential to their functions in practical devices. Because of the high boiling points of the fluorinated additives, only a small percentage of these additives can be applied in the mixture to ensure low-temperature application of the products.

- Key conclusions: Like SF6, there are limitations in applicability of alternative gas mixtures based on C4-FN or C5-FK with respect to liquefaction at very low operating ambient temperatures. Limitations for C4-FN-based mixtures in HV apparatus as well as in the case of using C5-FK in MV devices are reported at around -30°C. For C5-FK in HV-circuit breakers, the limitation is published to be around -5°C, but also pilot installations for passive elements like busbars are reported to be applicable down to -25°C.

In chapter 2, critical interruption parameters of SF6-free gas circuit breakers are compared with those of SF6. Actual measurements of transient gas pressure, arc conductivity, post-arc current, arc voltage and dielectric recovery are assessed regarding their impact on performance and compared with SF6. As a general conclusion, none of the SF6-alternative mixtures can directly match the performance of SF6, but by increasing the operational pressure from around 0.6 to 0.8 – 0.9 MPa and some adaptions in the lay-out of the arcing chamber and overall dimensions in HV circuit breakers and GIS, similar performance is reported. The content of the fluorinated constituent in high-voltage components, when present, is 3 - 8%. CO2 gas is reported to be the optimum carrier gas, whereas several percent of O2 is added (in most cases) to reduce soot and CO formation by arcing.

- Key conclusions: Current interruption using those low-GWP mixtures pose special challenges regarding some switching duties (e.g., the short-line faults). There is a manufacturer consensus that in comparison to SF6 circuit breakers, those challenges can be solved with moderate efforts like, for example, small design changes, higher filling pressures or increased opening speed.

Chapter 3 is on lifetime aspects. Since gas mixtures are under discussion, new definitions of conditions of the gas are necessary. Pressure, in the SF6 case the only gas characteristic is no longer enough since also the mixture composition might change over time and may impact the lifetime of switchgear. Two gas loss mechanisms that may lead to change of gas composition are discussed and quantified:

- Loss by leakage and permeation. It is demonstrated that leakage is similar for each of the gas components, but permeation gives rise to much higher loss of CO2 than C4-FN / C5-FK. Experiments show that the change in gas mixture composition is negligible, when dedicated sealing is used.

- Loss by decomposition under arcing. A new factor to consider is decomposition of C4-FN / C5-FK by arcing. This “gas wear mechanism” is numerically compared with the wear of arcing contacts and nozzle (as usual in SF6 breakers). With the knowledge so far, it is concluded that gas decomposition in properly designed equipment is not a lifetime limiting factor compared to other degradation mechanisms.

Various environment, health, and safety aspects of the by-products created by arcing in new fluorinated mixtures are presented. It is argued that in normal operation the by-products created by arcing fall in the same acute toxicity classification as arced SF6.

- Key conclusion: The operability, performance, maintenance, and lifetime of alternative gases appear to be similar to SF6.

Chapter 4 is on high-voltage switchgear, other than circuit breakers. In GIS, (high-speed) earthing and disconnecting switches must operate directly in the new mixtures, including technical air. The impact of this condition is studied in detail for all functions of these switches.

- Key conclusion: Proper scaling and/or redesign is needed to adapt the switches to their new environment; but no principal differences arise.

Chapter 5 is on testing and standards. For SF6, most short-circuit test-duties require “minimum pressure” prior to testing as the most critical condition. Since pressure is no longer the sole key qualifier for the gas mixture condition, the “type-test gas composition and pressure” must be set prior to a testing. Because of the loss of the primary C4-FN/C5-FK gas component by arcing, testing using the smallest gas enclosure (if more than one exists) in which a specific switching device will be housed is recommended.

Key conclusions: Detailed analysis does not result in additional test requirements. Thermodynamic behaviour of alternative gases is different from that of SF6; testing at “minimum functional pressure” will become “type-test composition and pressure”. The importance of the voltage condition check and the order of composite tests (e.g., class C2 capacitive switching and class E2 electrical endurance) may be elevated relative to SF6 due to the influence of both decomposition, by-product generation and lack of experience. Shunt reactor switching has not been reported yet allowing no conclusions for testing.

SF6-free switchgear products and projects

The chapters 6–8 list available products and ongoing projects.

Chapter 6 is on HV vacuum circuit breakers. This chapter is an update to the CIGRE TB 589 from 2014 that details the technology of high-voltage vacuum circuit breakers. In the present Brochure, new installations from 11 manufacturers in service are highlighted, showing a rapid increase of high-voltage vacuum circuit breakers mainly in Japan and US. Whereas the technology presented in 2014 was almost exclusively SF6 insulated switchgear, the main technology progress reported here is the availability of SF6-free vacuum circuit breakers up to 170 kV in single break design. Modern products in dead-tank (DT), live-tank (LT) and GIS design use technical air in the pressure range 0.8 – 1 MPa.

- Key conclusion: Natural-origin gas insulated vacuum circuit breaker technology is already available up to 170 kV.

Chapter 7 is an inventory of new MV SF6-free switchgear. Many different MV switchgear concepts exist, and this chapter makes an inventory along its functions. In MV switchgear, a higher relative amount of C5-FK (> 10%) in the mixture is used because of the lower operating gas pressure which makes it still suitable for lower ambient temperatures. In many types of MV switchgear, alternatives replace SF6 for insulation. Also, novel examples are given of load-break switches (LBS) in which a C5-FK based mixture is used for interruption.

- Key conclusion: MV switchgear products operating with fluorinated alternative gases are at present available up to rated voltage of 40.5 kV.

Chapter 8 lists the existing projects, mostly in Europe and Korea, of SF6-free gas circuit breakers. Most operate with a C4-FN / O2 / CO2 mixture (GIS, DT), followed by C5-FK / O2 / CO2 (GIS) and CO2 / O2 (LT). In some cases, as risk mitigation, the circuit breakers are installed in systems having a (much) lower voltage than the breaker’s rated voltage, which is at maximum 170 kV with 50 kA as rated short-circuit breaking current. The available technologies seem to offer similar switchgear ratings except for the minimum operating temperature where O2 / CO2 mixtures are offered down to -50°C, C4-FN mixtures down to -30°C and C5-FK mixtures down to +5°C. Differences in GWP are prominent: C4-FN mixtures have GWP 300 – 750, whereas C5-FK- and natural-origin gas mixtures have GWP ≤ 1.

- Key conclusion: HV switchgear products operating with alternative gases as an interruption medium up to 170 kV are available at present.

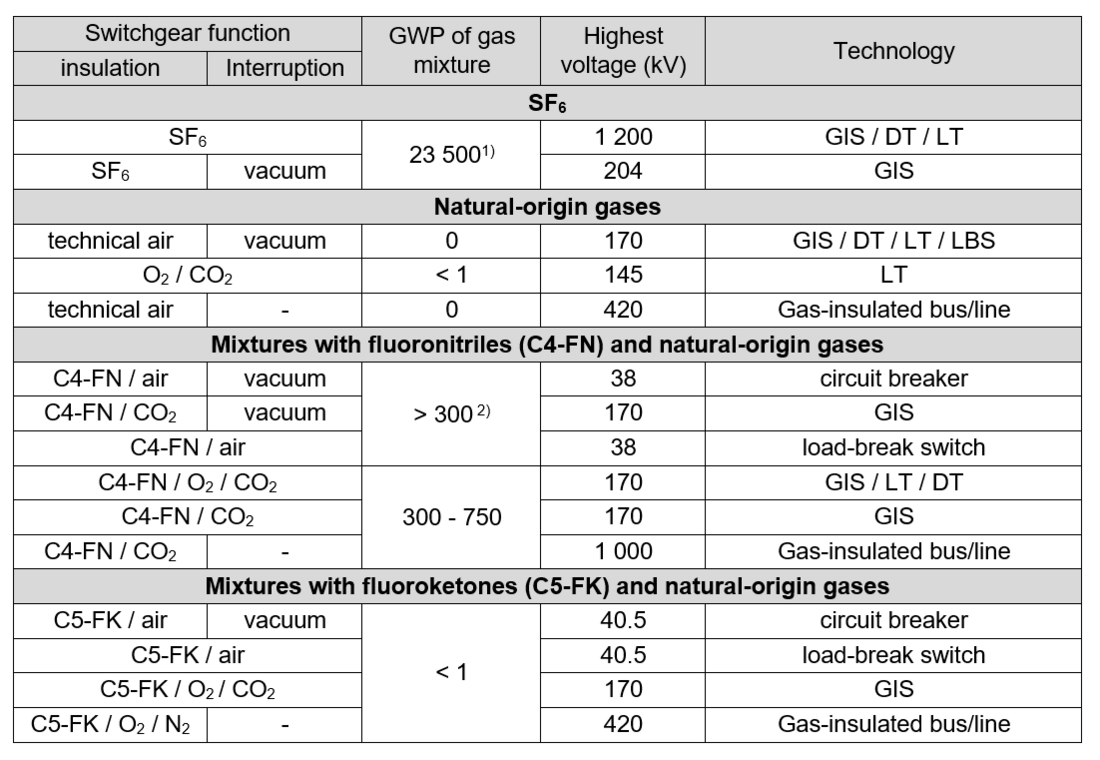

In Table 1, an overview is presented of SF6 and SF6-free switchgear presented in the Brochure [2].

Table 1 - List of available SF6-free switchgear for different voltage levels

Ownership and operation

Chapter 9 deals with ownership and operation. Insight is given to SF6 leakage reduction efforts and results. It is concluded that verification of gas leakage in a type-test, and its interpretation regarding the change in composition, is not yet well developed, nor standardised. An overview is provided of SF6 emission reducing regulations in various countries.

Reservation is expressed towards the acceptance of upcoming SF6-free alternatives on the following points:

- Clear information on maintenance and availability is needed, e.g., indicators that signal when the gas composition reaches a condition that needs top-up or replacement.

- Multiple mixtures and mixture-compositions may be needed in a substation and possibly even more than one gas in an installation. TSOs might prefer one sole alternative in their system, instead of installing several alternatives over time.

- There is some lack of confidence in the present test requirements due to uncertainty on “extreme conditions” of the new gases and after-test status verification.

- Manufacturers have focused on switching performance. However, restrictions regarding space, maximum continuous current and minimum temperature need to be considered as well.

- For vacuum switchgear, the level of x-ray emission (produced by interrupters in open position) needs to be investigated at EHV voltage levels to ensure safe operation. It is not an operational issue at 145 kV level.

- The total cost of ownership is unpredictable but is most probably higher than SF6-solutions. Ultimately, it is depending on regulator allowance for higher initial price and total cost of ownership.

Outlook

Development is ongoing towards switchgear with voltage ratings beyond the 145 / 170 kV levels, using both gas- and vacuum interrupter technology.

Vacuum technology: Manufacturers' studies suggest that 245 kV single-break GIS / dead tank products will be available within a few years. Because vacuum insulation levels do not scale linearly with switching gap length, the next rating (362 / 420 kV) will probably consist of two breaks. Developments in China propose multiple vacuum interrupters in series/parallel to realise higher voltage/current rating, possibly combined with fast electromagnetic actuators.

Gas technology: Reports are issued showing successful type test of single break 245 kV dead tank designs with C4-FN mixtures. Announcement are made of 420 kV double break designs by 2022. There seem to be no physical limitations to exclude a 420 kV single-break type SF6-free gas circuit breaker. Manufacturers' road maps indicate 550 kV GIS by 2024.

Work is in progress towards natural-origin gas (CO2 / O2) circuit breakers, as an extension to higher ratings of the 145 kV live tank proven performance.

Investing in SF6-free equipment is seen by the working group as beneficial because of:

- A necessary and not negligible step in the decarbonisation of the electrical industry in line with politically set deadlines in major parts of the world.

- Gaining experience with the new technology.

- Stimulating manufacturers to develop “green” products.

- Mitigating the risk of carbon taxation, which might become excessive for SF6 with its enormous CO2 equivalent.

Additional information

More information on SF6-alternatives can be found in the following CIGRE Technical Brochures:

- TB 802: “Application of non-SF6 gases or gas-mixtures in medium and high voltage gas-insulated switchgear”, (CIGRE WG B3.45), 2020

- TB 849: “Electric performance of new non-SF6 gases and gas mixtures for gas-insulated systems”, (CIGRE WG D1.67), 2021

After the Study Committee review phase of this Technical Brochure, a new proposal is issued by the European Commission [3]), for the regulation of fluorinated greenhouse gases as a follow-up of the 2014 F-gas regulation. In the new document dates are proposed beyond which the installation and replacement of switchgear is prohibited with insulating or breaking medium using, or whose functioning relies upon gases with GWP of 10 or more, or with GWP of more than 2000, unless evidence is provided that no suitable alternative is available based on technical grounds within the lower GWP ranges referred above.

- [1] This number is likely to increase after final editing of the Greenhouse gas tables in the 6th IPCC Assessment Report (2022)

- [2] GWP value depends on the C4-FN composition ratio which varies strongly between different designs

- [3] Proposal for a regulation of the European Parliament and of the Council on fluorinated greenhouse gases, amending Directive (EU) 2019/1937 and repealing regulation (EU) No 517/2014, April 5, 2022.