Reliability of key T&D equipment: Test-laboratory- and field experience

Electrification of our complete society has never been as urgent as now, with the infrastructure for transmission and distribution of electrical energy as a key enabler of this process. Decarbonization, deregulation, decentralization, the three D’s, are the drivers for innovation. Let’s add ‘de-risking’, since reliability of infrastructure under the fast transitions related to the three D’s remains of prime importance given the increasing dependence on electricity. Rapid development of new technology is creating unfamiliar and unpredictable challenges, under pressure of time and costs, not to mention global competition, restructuring of the major suppliers and the coming of new players.

In this report, statistics from three decades of type-testing cable systems, transformers and SF6 circuit breakers is presented, collected by KEMA Labs, the CESI Group TIC Division, world market leader in testing and certification of T&D equipment. As a ballpark figure, around one quarter of these components submitted to a type-test, does not pass the test initially. If so, after modification of design, material, manufacturing the correct functioning is usually verified in a new round of tests.

By René Smeets and Bas Verhoeven

Cables and accessories

A cable system consists of a cable and its accessories: joints and terminations. The system’s insulation is designed to control the high-voltage stress which is verified by a series of dielectric tests under various operational conditions.

Laboratory test results are collected from over 1000 AC cable systems having (almost all) XLPE insulation. The test-objects are classified as “MV” (53% of components), when tested against IEC 60502 and CENELEC HD 6210 and HD 629.1 (including indoor and outdoor terminations), and “HV” (47%) when tested against IEC 60840 and IEC 62067 (including GIS and outdoor terminations).

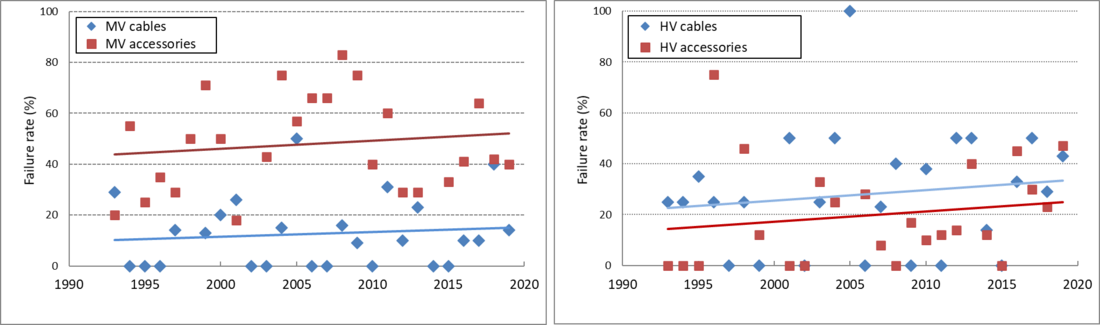

Figure 1 gives the observed initial test failure rates of cable and accessories over time (1993 - 2019). Trendlines are added, showing a slight net increase over the years (updated from [1]).

Figure 1 - Development of test failure rates of MV (left) and HV (right) cables and accessories 1993-2019

This survey shows that 10 - 50% of all components fail to pass the standardized type-test.

It is interesting to compare these data with failure data from service. CIGRE WG B1.57 (2020) [2] concludes a service failure rate due to internal causes of 0.069 /100 km.yr for cables (60 – 500 kV, XLPE AC land cable), which is 30% higher than reported in the earlier CIGRE survey from 2009 [3]. For joints this number is 0.002 / 100 units.yr (40% below the 2009 survey data) and for terminations a failure rate of 0.051 /100 units.yr is reported (300% increase from 2009).

Transformers

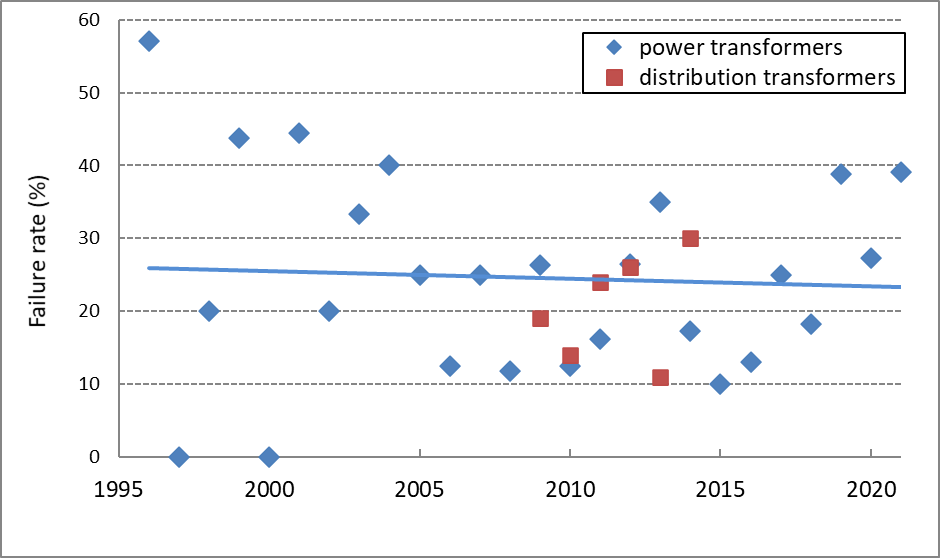

The most severe stress to transformers is passage of short-circuit current. In that event, the windings are subjected to very large electro-dynamic forces that shall not lead to deformation or other damage [4]. Tests to verify withstand of short-circuit are formulated in IEC 60076-5. Fig. 2 displays the experience with short-circuit testing of 251 distribution transformers (315 - 2000 kVA) in a six-year period and 423 large power transformers (LPT) (25 – 600 MVA, 33 - 800 kV) in 29 years of testing [5]. In both cases the test-failure rate is in the order of 25%. The most prominent failure mode is deformation of windings, but also external abnormalities such a as break of bushing, oil spill, tank rupture have been observed. The trend is almost constant, though the last six years the LPT test-failure rate heads upward.

Figure 2 - Test-failure rates of distribution- and power transformers 1993 - 2021

Short-circuit testing is not a type-test but is performed on individual LPTs prior to installation. The test is non-destructive and is acknowledged by CIGRE SC A2 as “the most comprehensive solution because all parts are verified”.

Transformer service failure data are collected by CIGRE in 2015 [6]. In this survey a (major) failure rate [7] of 0.53% is found (in the voltage range ≥ 69 kV). Winding failures were identified as the largest contributor (37%) to the in-service major failures, and external short-circuit is the second largest known cause (after ageing) of major failures.

Circuit breakers

Circuit breakers are the key protection hardware in the system: they must interrupt very high current in case of a fault in the grid. CIGRE has conducted various TSO surveys, from which a fault incidence of a few faults per 100 km overhead line per year emerges [8].

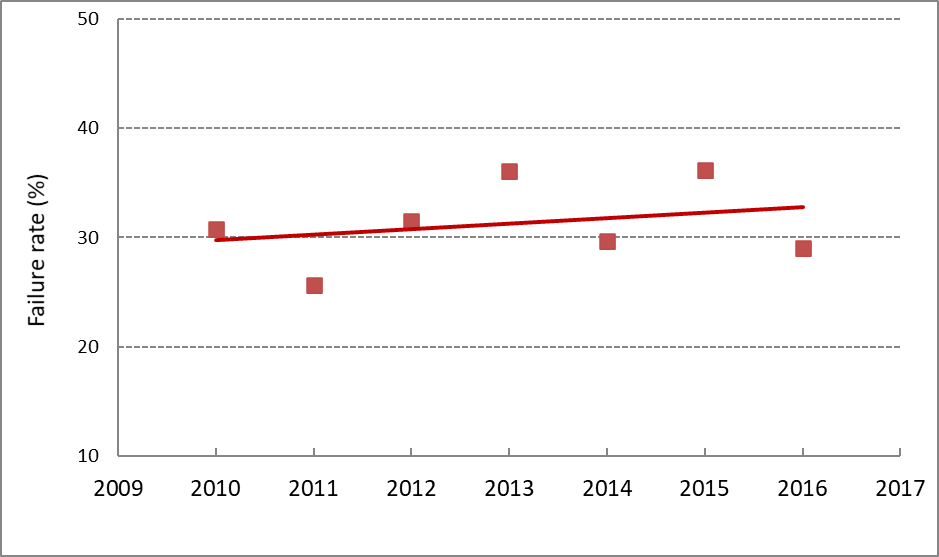

Test statistics of HV SF6 circuit breakers rated 72.5 - 800 kV, being subjected to 1241 standardized IEC short-circuit test-series between 2010 – 2016 are shown in fig. 3. The overall failure rate (to pass a test-duty) is 32%, and roughly constant over the years. Details can be found in [9] where it is demonstrated that the “short-line fault” test-duty is the most critical one to pass.

In-service field data are also available for circuit breakers and summarized in [10]. The latest information (2004-2007) shows an overall failure rate of 0.30% [11], down from 0.67% in the period 1988-1991. The period 2014-2017 is now under evaluation by CIGRE WG A3.48.

Figure 3 - Test-failure rates of HV circuit breakers 2010 - 2016

Conclusion

Improvement of materials, calculation methods and production technologies are ongoing, but these do not result in a decrease of failure rate in type-testing, which, over decades, remains in the 25% range. The in-service failure rate of power system components is much lower. This is because type-testing aims to verify the components compliance to the standards, which cover about 90% of practical applications.

In order to maintain the low service failure rate, type-testing and independent certification remains a key de-risking instrument to distinguish the well-designed, well-manufactured products from the inferior ones.

Thumbnail credit: Omid Armin on Unsplash

- [1] E. Pultrum, W. Sloot, J. Fernandez, R.P.P. Smeets, “High-voltage Cable Testing: Type Test Experiences and New Insights into Pre-Qualification”, 21st Conference on the Electric Power Supply Industry, Bangkok, 2016

- [2] CIGRE TB 815: “Update of Service Experience of HV Underground and Submarine Cable Systems”, CIGRE WG B1.57, 2020 - e-cigre.org/publication/815-update-of-service-experience-of-hv-underground-and-submarine-cable-systems

- [3] CIGRE TB 379: “Update of Service Experience of HV Underground and Submarine Cable Systems”, CIGRE WG B1.10, 2009 - e-cigre.org/publication/379-update-of-service-experience-of-hv-underground-and-submarine-cable-systems

- [4] R.P.P. Smeets, A. Derviskadic, S. Subramany, “Verification of the Short-Circuit Withstand Capability of Transformers”, CIGRE Sci. and Eng., No. 10, Feb. 2018 - e-cigre.org/publication/CSE010-cse-010

- [5] R.P.P. Smeets, R. Bruil, ”Experiences and innovations in power transformer short-circuit current withstand testing”, CIGRE Conference, report A2-304, 2016 - e-cigre.org/publication/A2-304_2016

- [6] CIGRE TB 642, ”Transformer Reliability Survey”, CIGRE WG A2.37, 2015 - e-cigre.org/publication/642-transformer-reliability-survey

- [7] Failure rate = (number of units failed/operating unit years) x 100 [%/yr]

- [8] CIGRE TF A3.01: “Statistical Analysis of Electrical Stresses on High-Voltage Circuit Breakers in Service”, Electra 24, No. 220, 2005 - e-cigre.org/publication/ELT_220_2-statistical-analysis-of-electrical-stresses-on-high-voltage-circuit-breakers-in-service

- [9] R.P.P. Smeets, B. Baum, R. Nijman, D. Petropoulos, T. Ohtaka, “High-Voltage Circuit Breaker Test Statistics 2011-2016 and Test Analysis Tools”, CIGRE Conference, report A3-102, 2018 - e-cigre.org/publication/SESSION2018_A3-102

- [10] CIGRE AG A3.01, ”CIGRE Reliability Survey on Equipment”, CIGRE Conference, report A3-201, 2020 - e-cigre.org/publication/session2021a3-sessions-2020--2021-sc-a3-package

- [11] CIGRE TB 510, “Final Report of the 2004-2007 International Enquiry on Reliability of High-Voltage Equipment – part 2: Reliability of High-Voltage SF6 Circuit Breakers”, CIGRE WG A3.06, 2012 - e-cigre.org/publication/510-final-report-of-the-2004---2007-international-enquiry-on-reliability-of-high-voltage-equipment---part-2-sf6-circuit-breakers