Guide for Cleanliness and Storage of Generators

The last two decades have seen major shifts in the power generation landscape which has resulted in cancellation or postponement of new build power stations or a change in generation technology. The underlaying causes are mainly linked to climate change policies to reduce CO2 emissions and to shift the power generation base from traditionally fossil-fuelled to more sustainable and renewable energy sources. This has been combined with fluctuations in the electricity market coupled with economic downturns.

Members

Convenor

(CH)

K. MAYOR

B. ADAMS (UK), V. FERNAGUT (FR), V. TARTAGLIONE (IT), M. SINISCALCHI (BR), J. MICHALEC (USA), H. NISTELBERGER (DE), W. MOORE (USA), C. FENGBO (CN)

Introduction

This situation results in high value, strategic power generation equipment being put into storage whilst projects re-adjust, either as individual components or, in some cases, as fully assembled units.

This has exacerbated the normal issues faced by power generation manufacturers and utilities in preserving and monitoring stored equipment and major strategic spares.

A related topic of interest in Study Committee A1 was that of cleanliness when carrying out generator assembly, maintenance, or repair work on site.

This raised the question of what is considered good industry practice for the storage conditions, environmental control, type and frequency of testing/monitoring and cleanliness procedures put in place during the various storage and assembly periods to ensure a successful preservation of the equipment.

CIGRE therefore launched a working group to understand the different approaches established worldwide and see if there was a case for a consolidated guidance document for the overall power generation community.

The result of this work, a Technical Brochure entitled “Guide for Cleanliness and Storage of Generators”, is described in this article.

Scope and Methodology

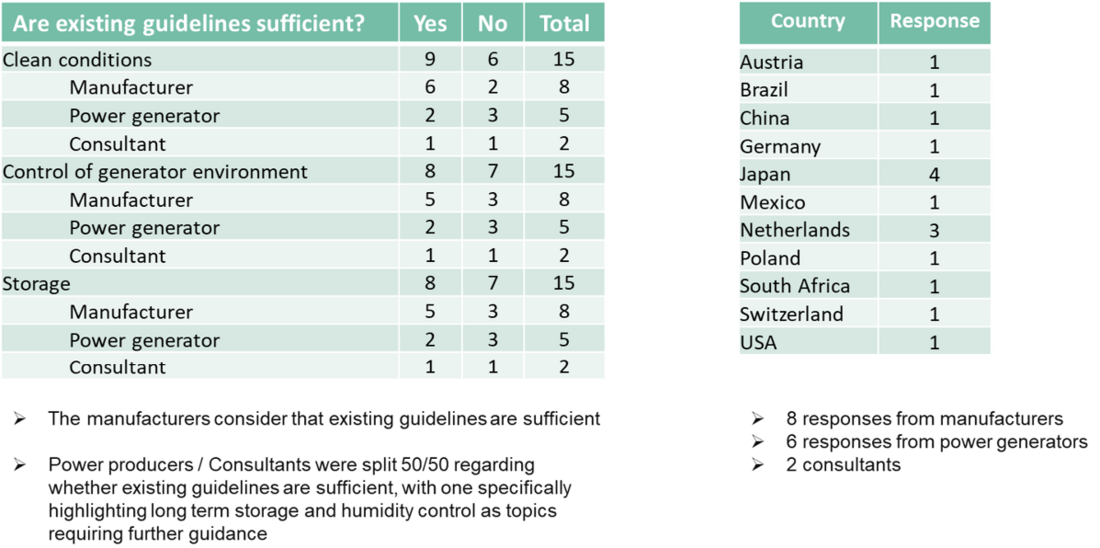

A questionnaire was raised to gather existing practices on the topics of recommended storage conditions, preservation techniques, monitoring and testing of equipment in storage, and a general question asking if existing guidelines are sufficient.

Figure 1 shows the response to the questionnaire.

Figure 1 - Summary of Questionnaire responses

The responses showed that manufacturers considered that existing guidelines were sufficient, while power generators and consultants tended towards the opinion that they were not.

A decision vote, taken within the Study Committee, concluded that a CIGRE guide on the topics related to generator cleanliness and storage would be a valuable contribution to the community. The guide would take into account the best practices gained from the detailed responses to the questionnaire, and input from the working group members and reviewers.

Description of the TB

The Technical Brochure gives guidelines on cleanliness, transport, storage and preservation of large generators and their associated main components after shipping from the Original Equipment Manufacturer (OEM), but the practices can be applied to other similar electrical equipment where appropriate.

The guide is organized in 4 main sections for ease of reference:

- General considerations regarding cleanliness and storage

- Preservation of generators and specific components

- Preservation during generator assembly and maintenance outages

- Preservation/mothballing of the assembled generator

The Appendix gives additional guidance on specific preservation and dry-out methods.

Cleanliness and Storage – General Considerations

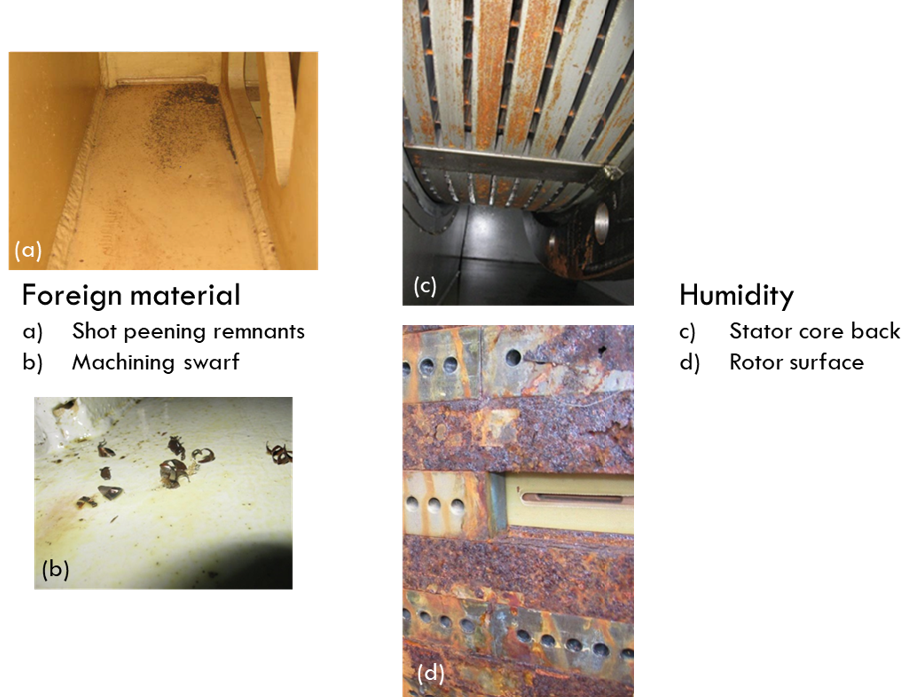

Chapter 2 describes general considerations regarding cleanliness and storage, in particular to the primary causes of equipment damage: ingress of debris and foreign particles, temperature and humidity, mechanical support and protection against impact damage, and transport. Some examples are given of failure to control these aspects – Figure 2 shows a couple of extracts from the guide.

Figure 2 - Examples of clealiness and storage issues

Storage of Generator Components

Chapter 3 provides guidance on the storage of generators and associated components. General recommendations appropriate to most equipment are followed by specific recommendations by component:

- Stator bars

- Complete stator / Stator windings

- Rotor coils

- Retaining rings

- Insulation materials

- Complete rotor

A summary table is included for easier reference giving guidance for each component under the following headings:

- transport/storage conditions;

- specific requirements/considerations;

- parameters to be monitored;

- explanatory comments on the monitored parameters.

Preservation during Assembly and Outages

Preservation during initial equipment assembly and during outages for maintenance and/or repair needs careful consideration and implementation. During such work equipment can often be open to the local ambient air and sudden changes in temperature and humidity can result in condensation and corrosion on sensitive equipment and in areas that are difficult to access, view or clean.

Chapter 4 of the guide covers the setting up clean conditions with restricted, controlled access, control of material brought into and out of the restricted zones, control of ambient conditions, and training.

Preservation of the Complete Generator

Occasionally generators are mothballed in the completely assembled condition. This may be due to unexpected project delays or delays in return to service or due to partial closure of an operating plant while a decision on decommissioning or re-purposing of the plant is being assessed, e.g., converting to synchronous condenser duty.

Chapter 5 covers this topic in three categories:

- Short term preservation during maintenance outages;

- Medium term preservation for extended outages, or where cold ambient conditions are expected;

- Long term preservation for extended stoppage periods, or mothballing, of several months/years.

General considerations are given for each of the above categories, followed by guidelines on specific aspects:

- Internal space

- Gas System and Shaft Seal Oil System

- Stator Water System

- Rotor

- Bearings & Jacking Oil

- Exciter/Brush Gear & Sliprings

- Instrumentation

- Cubicles

- System Pipework

Preservation

Some general aspects of preservation are given in Appendix C of the guide. Part 1 of the appendix covers preservation methods:

- Desiccant

- Inert atmosphere

- Dehumidifiers

Part 2 gives additional information of generator dry-out methods usually carried out prior to operation, storage, or shipment, but also to enable electrical testing of the windings. General information is followed by a specific discussion on the dry out of water-cooled stator windings.

Conclusions

Damage to components due to lack of cleanliness and proper storage is very much avoidable and usually at reasonable cost compared to the cost of repair or replacement. The rules are relatively straightforward:

- Avoid that foreign material gets into the equipment/packaging;

- Keep the equipment in a non-corrosive environment with no chemical pollutants;

- The ambient air/preservation medium shall be kept at a sufficiently low humidity, taking into account the dependency of humidity on temperature;

- Control or restrict the daily temperature range and rate of variation;

- Ensure equipment is properly supported to avoid distortion;

- Ensure that protective packing, anti-corrosion varnishes, sealed wrapping, tapes and other sealants are intact;

- Make regular checks on humidity and temperature & replace/regenerate desiccant when necessary, or apply dehumidifiers;

- Keep a record of checks/inspections and measured data in the form of a storage log.