Inspection and testing of tools, equipment and training for live-line work on overhead lines

If an Electrical Utility worker relies upon equipment as an insulating component which fails to meet the standard integrity, serious, even fatal injuries may occure. To meet worldwide standards of reliability, safety as well as compatibility, a robust Electrical Testing and Certification program or Safety Management System should be applied by electrical utility companies.

Members

Convenor

(HU)

B. NEMETH

Secretary

(SI)

V. LOVRENČIĆ

J. AAL (NO), P. KOMAROMI (CA), C. ATLANI (FR), C. LAND (UK), J. BÁCSKAI (SK), A. LOVRENČIČ (SI), T. CARREIRA (CA), M. OLTEAN (RO), K. DÜTSCH (DE), H.P. PAMPEL (DE), S. ERMAN (TK), A.A. PARIZIA (IT), G. GÖCSEI (HU), A. PRICE (AU), T. JORDAN (DE), K. SOLUM (NO), M. KELLETT (CA)

Corresponding Members: S. CHABIN (FR), A.D. PIERCE (UK), E. MARSHALL (ZA)

Introduction

The first part of the document is designed to provide accurate reference information on best practices and techniques. It includes guidelines of existing International Standards specific to Periodical Testing and Certification of tools and equipment that are used when working in the vicinity or directly on the energized lines and equipment. The second part of this document considers the importance of the live working training programs.

It has been documented that investment in training is an essential requirement for providing safe and competent personnel in the workplace. Work environments with trained and competent personnel contribute towards the provision of an accident free worksite, improvements in productivity and overall quality of the work produced.

Understanding the importance and benefits of training, transmission and/or distribution companies should have a structured training program in place for live working on overhead lines at their respective system operating voltages (distribution and/or transmission).

The content of the training part of this document is a compilation of experience from international overhead line live working specialists and should be considered as the minimum requirements for training in live working on overhead lines.

When reading the TB, and considering implementing the content, reference must be made to applicable statutory national regulations, company specific procedures and any additional specific requirements to ensure full compliance.

Figure 1 – Live working course in a training centre

Scope

The scope of the first part is to provide accurate reference information on best practices and techniques regarding inspection and testing of live working tools, equipment.

The scope of the second part is to carry out a review of the various international standards, procedures and regulations relating to training for live working on overhead lines. This part also analyses the benefits of delivering training in live working on overhead lines.

Description of the document

The document covers two major topics. The first one is the inspection and testing of tools, equipment that are used during live working, which is distributed in six chapters. The second part is about training, which is distributed in nine chapters.

Inspection and testing of tools, equipment

- Introduction – serious, even fatal injuries may occur if an electrical utility worker is using equipment that is relied upon as an insulating component and it fails to meet the standard insulation integrity. Thus it is essential to meet the corresponding standards, however, there are regional differences in standards.

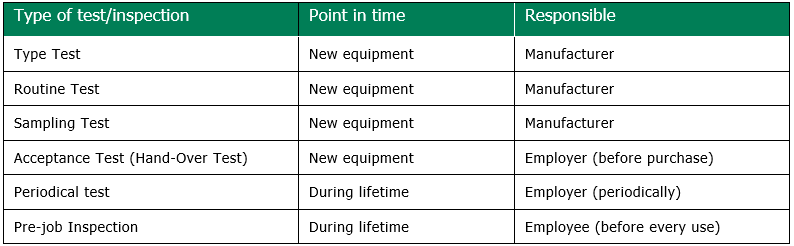

- Different type of tests – gives definitions for several testing method, states the purpose of the tests and the regularity they should be carried out. Names the facility responsible for carrying out the tests.

Table 1 - Responsibilities regarding to different types of tests and inspections

- Conditions of usage of live working tools, devices and equipment – defining the criteria and the time interval for periodical testing requires an understanding of conditions/stresses during live working, preparation and follow-up of the work as well as storage and transportation, frequency of usage, and aging properties of the material. This chapter gives several examples of how an external factor can affect certain factors of an instrument.

- Requirements and references for periodical testing – briefly summarizes the different regional regulations regarding periodical testing.

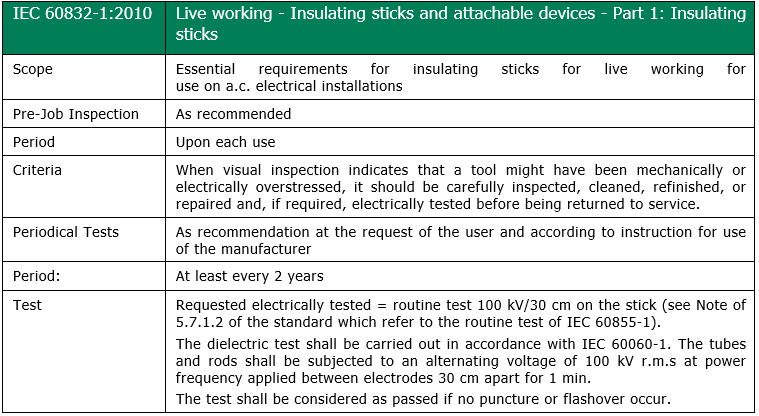

- Periodical Testing Requirements and guidelines – gives detailed description for the periodical testing of several live working tool/equipment, including the corresponding standards, the test arrangements and Working Group suggestions.

Table 2 - Extract from IEC 60832-1:2010

- Laboratories – laboratories performing tests on live working (LW) tools and equipment should meet the requirements of ISO/IEC 17025 or ASTM D2865-06 (may not need to be accredited). The scope of these standards specifies the general requirements for competence when carrying out the test. Thus, it is specified that the laboratory must have knowledge, equipment and the skilled personnel necessary to carry out the tests. Furthermore the laboratory must have a unified documentation system that meets minimal requirements, which are given in this chapter.

Training for live working

- Introduction – states that investing in live working training is essential and gives a summary of the following chapters.

- Terms and definitions – defines live working and the different methods used during live working. This document also defines the live working training types.

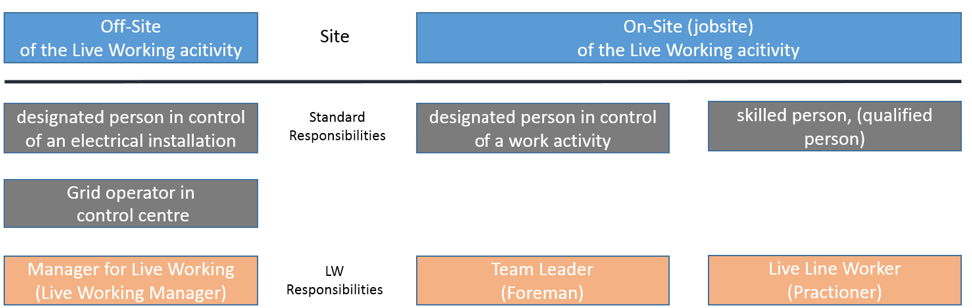

- Roles and responsibilities – to guarantee the safety measurements to be followed, there must be different responsibilities, both on-site and off-site.

Table 3 - Roles and responsibilities during live working activity

- Global approaches to LW training – summarizes the two main methods of training in live working. This document also gives a comparison between these two, which are called “Approach A” and “Approach B”.

- Standards, Directives and Regulations Applicable for LW Training – this section details some examples and guidance on the standards, regulations and directives that are applicable for LW training in specific parts of the world. Referencing the information provided in this section may be useful when considering introducing LW methods and the required LW training.

- Delivering live working Training – this chapter details the necessary information required to establish a LW training program, addressing both Basic LW training and Refresher LW training. The presented information shall cover all methods of LW training identified in the General Requirements part of this chapter. The second and third part consists of information (e.g. theoretical and practical content) which is specific for Basic LW Training and Refresher LW training, respectively.

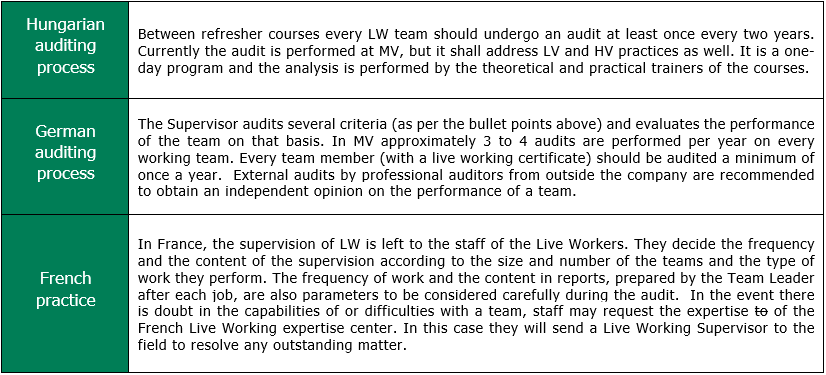

- Guidance on Auditing of live working – the purpose of an audit is to ensure compliance with the company policies, procedures and applicable statutory national regulations or directives. This section gives a general requirement on what an audit should include. Furthermore three different (Hungarian, German and French) auditing process are presented.

Table 4 - Examples of different LW auditing processes

- Audits and quality systems for LW training centres – this section details the recommended quality control systems required to evaluate the adequacy and quality of the current training practices used in LW training centres. These audits can be performed by an independent organization, third party organizations (e.g. independent associations) or they can be from internal quality departments of the same company. Demonstrating compliance results in acquiring an independent accreditation depending on the country specific requirements and standards.

- International recognition of LW training certificates – this chapter details the acceptance of foreign LW training certificates. In the territory of the European Union (EU), because of the diversities of country-dependent regulations, the attitude towards domestic and foreign LW certifiers may be very different. While the EU directive is based on standardisation, when employing foreign workers, it is necessary to have a certificate that meets the requirements of the country in question. It may also be necessary to learn the language of the country.

- In the USA and Canada the different companies could have different working methods. When they require external help from another company, they enter into some sort of contract with each other. It means that the partners have certification of insurance and safety contracts in place.

Conclusion

The first part of the document covers the inspection and testing of live working tools and equipment, while the second part of the document covers the training procedures of live workers.

The document provides a general introduction but also gives a number of individual examples from several nations. The general part introduces definitions and the corresponding international standards, supplemented by individual national requirements.

On the basis of content, the first part of the document processes the types of tests and justifies their use. Particular emphasis is placed on the conduct of periodic tests and the requirements for conducting these.

The second half of the document also starts with an introduction of concepts, but focuses on how the training of workers takes place and what are the basic expectations of the trainees. It also describes the international acceptance of the certificates awarded.