Hydrogen, Power to Gas (P2G) and Gas to Power (G2P): Interesting technologies which need additional R&D and analyses within a system approach

The current use of wind and photovoltaic generation pose several challenges to their increasingly strong penetration. The use of energy resources that do not generate CO2 emissions is becoming increasingly important. The idea of green hydrogen, produced by electrolyzers fed with electricity from renewable sources, which by burning generates water, is more compelling today considering the new needs of the electrical power systems with the explosion of wind and solar generation, taking care of its possible multi-sector uses as well.

Hydrogen was discussed a great deal in the session “Hydrogen: Bridging sectors and regions” as part of the September 2019 World Energy Congress in Abu Dhabi. [1]

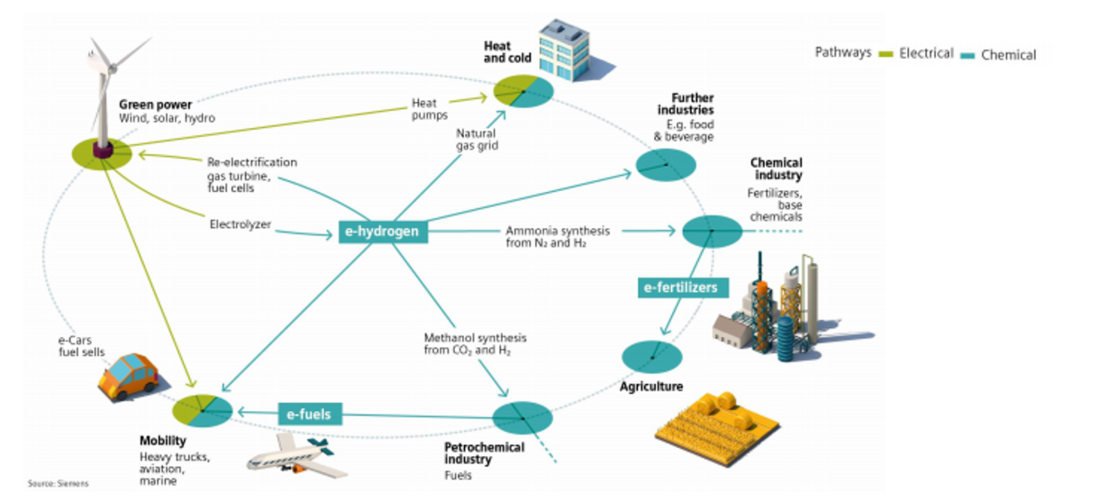

Figure 1 - e-hydrogen for deep decarbonization of all end user sectors. Source Siemens

The great technological potential of hydrogen has clearly emerged (Figure 1 [2]), both to replace fossil fuels in current hydrogen production (and here the emphasis has been on electrolysis) and for the use of hydrogen instead of fossil fuels in various domestic, transport and industrial energy uses. Hydrogen for storage of electricity has also been highlighted and its possible use as feedstock to produce synthetic methane.

Current and future scenarios of production and consumption of H2

The data presented in Abu Dhabi showed current annual H2 production values ranging from 80 to 110 million tons; something more than 40% comes from methane (STM process, Steam Methane Recovery), 30% from hydrocarbons, 18% from coal and only about 4% from water electrolysis. Current production involves significant emission of greenhouse gases (with the STM process, 1 kg of hydrogen corresponds to 8 – 9 kg of CO2) and is therefore referred to as “black hydrogen.”

From IRENA data, 33% of hydrogen is now used in refineries, 27% in ammonia manufacturing, 10% to produce methanol, 4% in steel and the remaining in various industrial processes [3]. The future use of hydrogen varies with the Hydrogen Council estimating an increase of 5.5 times by 2050 with IRENA estimating a little more than doubling. The shares in end-use sectors are quite different: IRENA considers 66% industry, 20% buildings and 14% transport while Hydrogen Council sees 45% industry, 29% transport,14% buildings and 12% power generation (not considered by IRENA)

To achieve a strong demand for green hydrogen, the following key factors emerged in the presentations and discussions for a production concentrated on electrolysis: a low cost of producing electricity from "close" and dedicated renewable sources, the investment cost (CAPEX) of electrolyzes and their lifespan, the hours of annual use (not so high in many locations due to photovoltaic or wind plants). and the costs of O&M. including spare parts which do not seem negligible in some cases.

The cost of the current “black hydrogen” assessed at site of production, is in the range of 1.25 - 2.5 $/kg. The present cost of “green hydrogen” produced by renewables according to Hydrogen Europe around 7.8 €/kg.

IRENA assumes that in 2050 hydrogen at the exit of the electrolyzer would cost 1.4 $/kg with the following assumptions; CAPEX of electrolysis plant at 200 $/kW and cost of electricity of 20 $/MWh with renewables load factor of 4,200 hours per year (combined values for electricity difficult to be considered for Central and Western Europe).

Hydrogen Europe is predicting a cost of hydrogen in Germany at around 3 €/kg in the mid-2030s, with a CAPEX of electrolyzer more than halved to 500 €/kW (present value), efficiency 66% with 100 MW electrolyzers and 50 €/MWh for renewable energy (offshore wind with load factor of 4,500 hours per year).

Considerations on power to gas and gas to power

The three main alternatives for use of hydrogen at present with priority of involvement are all starting with the production of green hydrogen via electrolysis of water and they are:

- Direct use of hydrogen for a variety of applications and possible storage/reconversion to electricity.

- Hydrogen as feedstock with CO2 to produce methane (according to the exothermic reaction ??2 + 4?2 → ??4 + 2 ?20 + heat) with all the present well known and reliable facilities for CH4 transportation/distribution/utilization and electricity generation, and

- Hydrogen to add CH4 content to bio-methane transforming its CO2 and CO by products to methane with H2.

All are clearly dependent on the cost of H2 production and for B) and C) for transportation to the “factory“ for production of methane if not coincident with the electrolyzer facility.

Conclusion

The relatively low cost of black hydrogen is inhibiting the widespread development of green hydrogen. To lower the price of the green H2 from electrolysis a drastic reduction in the costs of electrolyzers and the production of renewable electricity with an increase in its equivalent operating hours (load factor) is required.

The direct transformation of H2 to electricity, assuming in the medium term cost at 3 €/kg, with a transformation into electricity with efficiency of around 50%, the pure fuel costs results are 180 €/MWh (to which capital charges and O&M costs of a GTP plant tailor made for H2 use must be added taking care the utilization factor). This is compared to around 25 €/MWh for the component of fuel cost in EU in a natural gas CCGT plant (to which capital charges and O&M costs of a conventional and well experienced plant must be added taking care the utilization factor).

Considering the low specific energy content of H2 per liter with respect to CH4 (less than 1/3) both in the gaseous and liquid state (apart from safety standards), the transportation of hydrogen is more expensive with respect to methane. The transportation of H2 in the liquid state (-253°C) would require about 1/3 of the energy contained in 1 kg of hydrogen for liquefaction alone and the energy needed to keep the low temperature.

A 5% in volume blending of H2 with CH4 in existing pipelines provides an energy content per unit volume of around 1.6% with a reduction of 3.4% in the calorific value of the mixture, and an extreme blending of 20% (6.5% in energy), this would reduce the energy content of the mixture of 13.5% (with impossibility of interconnection of the specific pipeline in the gas grid). This blending does not appear a strategic choice.

More technical and economic analysis is required with long term experiments to predict the best option between massive sectorial use of H2 and a spread use of synthetic methane from H2 as a feedstock with CO2 and making use of present gas infrastructures. It is recommended we proceed thoughfully.

Note

This article is an extended version and translation into English of the Italian paper of A.Clerici: “Idrogeno, tecnologia interessante ma adelante con juicio” published by Nuova Energia Vol 1-2020

- [1] (a) A.Clerici:”Energy transition with holistic, pragmatic and sustainable approaches. PART 1: Global energy resources and outstanding development of wind and solar” - No.304 - June 2019 ELECTRA (b) A.Clerici:”Energy transition with holistic, pragmatic and sustainable approaches. PART 2: Challenges for integration in electricity systems of variable renewable energy resources” - No.305 - August 2019 ELECTRA

- [2] Manuel Kuehn, Siemens UAE: ”Hydrogen – Bridging Sectors and Regions” - Paper presented at the “Hydrogen: Bridging Sectors and Regions” event in Abu Dhabi 20 September 2019 during 24th World Energy Congress

- [3] Asami Miketa, IRENA: ”Hydrogen from Renewable Power Technology Outlook for the Energy Transition” - Paper presented at the “Hydrogen: Bridging Sectors and Regions” event in Abu Dhabi 20 September 2019 during 24th World Energy Congress