Impact of Cycling on Large Electrical Motors

Conventional power plants in many parts of the world are increasingly required to operate flexibly to facilitate both larger penetration of renewable energy and commercial considerations of operating in peak demand periods. Cyclic operation including two-shifting, operating at minimum load, and fast ramp up/down have all become normal for many power plants, even from quite an early stage of plant life. Operational flexibility is crucial for the commercial success of power plants.

Members

Convenor

(IE)

J. DOYLE

E. TORTELLO (IT), T. BECKWITH (US), P. CURIAC (RO), L. LEROY (FR), H. SEDDING (CA)

Contributors

B. O’SULLIVAN (IE), E. FIGUEIREDO (BR)

Introduction

Electrically driven motors are a vital component of the power plant auxiliary equipment, in particular in cases where the drive is critical to the power generation process such as cooling water supply, boiler feed pumps and boiler air-flow fans. For these large drives, motor ratings are typically several MWs, and the reliability of the power plant is dependent on these motors starting and operating reliably.

Cycling operation will cause various forms of deterioration of electric motor components which can lead to motor failure. Typical failures that have been attributed to cycling operation include material fatigue arising from torque stresses on rotors during starting and stopping, and high starting currents causing thermal and electromagnetic effects.

Bus transfer arrangements, where switchboards and loads are transferred from once source to another, are common in power stations as well as general industrial plants. Bus transfer can occur for a number of reasons including regular changeover during plant start-up and shut-down, as well as emergency transfer during fault situations to maintain continuity of supply to auxiliary loads.

Scope/ methodology

The study was limited to motors greater than 250kW. The harmful effects of motor starting are common to both induction and synchronous motors, however synchronous motors are typically started using Variable Speed Drives (VSD) therefore the effects are generally more common in squirrel cage induction motors. The study concentrates in particular on the effects of Direct On-Line (DOL) starting of motors and the effects on motors of bus transfer arrangements, which is common in power stations.

The Working Group has undertaken a general review of motor failure experience and previous research on the topic. International standards and guidelines have been reviewed and recommendations are made to improve the suitability for motors operating in such situations.

Description of the Technical Brochure

The Technical Brochure (TB) is structured as follows:

- Review of previous relevant research

- General discussion on the impact of plant cycling operation on plant auxiliaries

- Review of Bus Transfer schemes and their effects on motors

- Review of motor thermal, mechanical and insulation failures mechanisms attributable to cycling operation

- Review of motor starting methods

- Review of relevant International Standards & Guidelines

- Recommendations

Previous Research

Previous CIGRE research relevant to this topic includes:

- WG 11.06 (1997) “Survey of Practices and Specifications of Auxiliary Motors of Power Stations” considered the number of permissible starts in quick succession, permissible supply voltage condition and permissible starting current at motor starting.

- WG 11.06 (2002) “Motor Condition Monitoring” undertook a review of motor online condition monitoring user experience.

- WG A1.08 (2010) “Power Station Large Motors requirements in the Field of Standards” reviewed user experiences in relation to national and international standards. Of particular interest in terms of applicability of the work of A1.54, the use of Adjustable Speed Drives (ASD) as a motor starting mechanism is relevant as this starting mechanism is one method of limiting the effects of frequent starting & stopping.

- CIGRE Working Group A1.19 (2011) “Motor Failure Survey” explored motor failures to identify if a correlation existed between motor failures and work conditions, load, start-stop frequency, maintenance policy for large motors. A number of topics arose such as consideration of motor availability versus efficiency motor starting methods, and motor maintenance regimes.

Impact of Power Plant Cycling Operation on Large Motors

Power plant cycling operation will result in increased auxiliary drives being started and stopped, and in some cases undergoing bus transfer more frequently compared to a base load plant. This can result in several mechanisms which lead to deterioration of electric motor components.

Two scenarios are considered in the TB in terms of the impact of plant cycling operation on motors in plants:

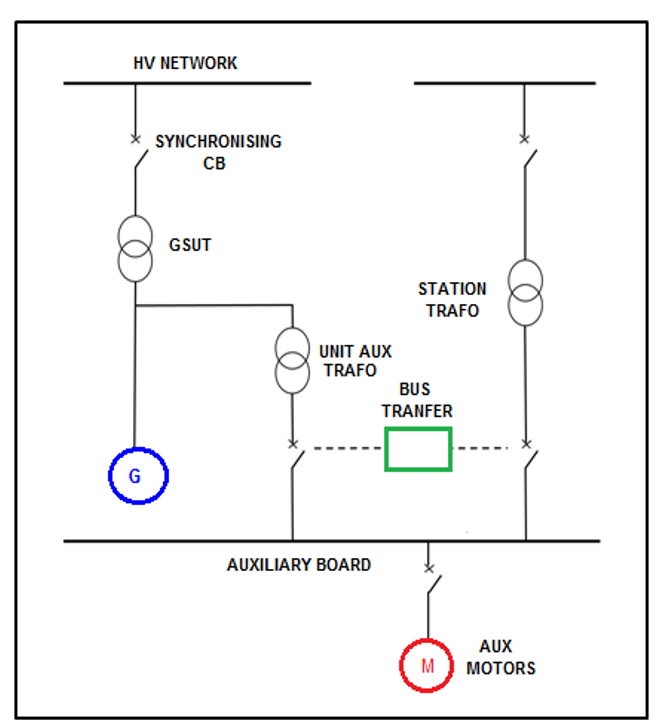

Scenario 1: Auxiliary loads are transferred from a station transformer supply to the unit auxiliary transformer supply during start up and shut down. A bus transfer system manages the transfer of auxiliary loads during start-up and shut-down. Generator synchronising to the HV grid is done at the HV breaker. See Figure 1.

Figure 1 - Bus Transfer Arrangement

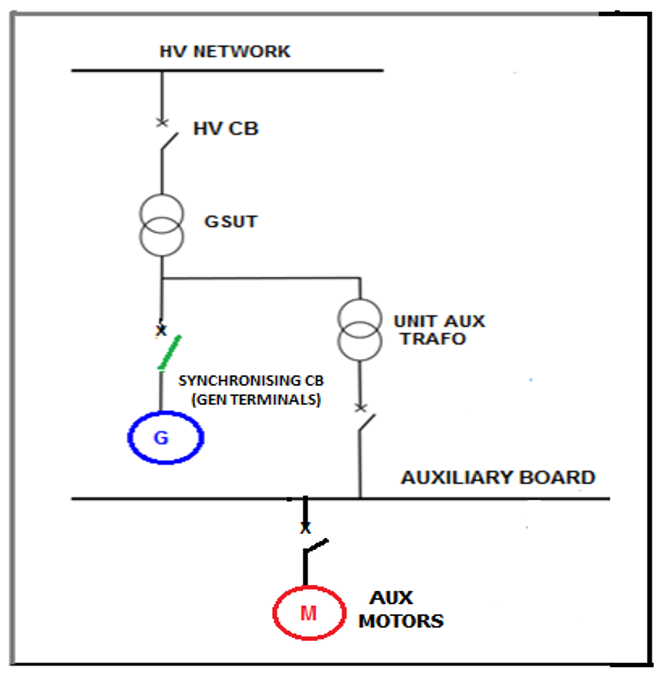

Scenario 2: Auxiliary loads are supplied from the Generator Step Up Transformer (GSUT) and Unit auxiliary transformer continuously during start up and shut down. No bus transfer is required. Generator synchronising to the HV grid is done at the generator circuit breaker. See Figure 2.

In Scenario 2, a failure of the GSUT or the UNIT AUX TRAFO will trip the HVCB, SYNCHRONIZING CB, and the UNIT AUX TRAFO CB, stop the auxiliary motors, with no possibility of a transfer, and possibly jeopardize a safe and orderly plant shut down.

Figure 2 – No Bus Transfer Arrangement

In both scenarios the auxiliary motors will experience starting and stopping, however in scenario 1 the motors will additionally experience the effects of bus transfer during each start and stop cycle. The effects of bus transfer are discussed below.

Effects of Bus Transfer

The TB deals extensively with the topic of bus transfer schemes and their impact on motors. Bus transfer involves the transfer of loads from one source to another, and this may arise during each normal plant start-up & shut-down, as well as during emergency situations when the primary source fails. International standards such as ANSI/NEMA C50.41-2012 “Polyphase Induction Motors for Power Generating Stations” and IEEE Std. C37.96-2012 “IEEE Guide for AC Motor Protection” are reviewed.

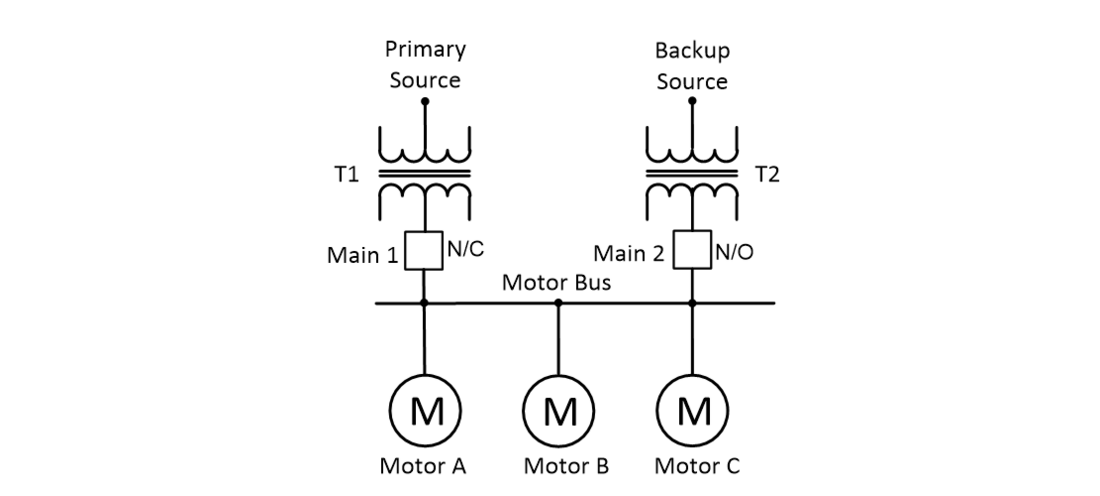

Figure 3 - Motor Bus Transfer One-Line Diagram Model

The ANSI/NEMA Standard C50.41-2012 Polyphase Induction Motors for Power Generating Stations, clause 14.1 states, “Induction motors are inherently capable of developing transient current and torque considerably in excess of rated current and torque when exposed to out-of-phase bus transfer.”. Further, “The magnitude of this transient current and torque may range from 2 to 20 times rated…” and continues that this “subjects the motor (including the motor windings) and driven equipment to transient forces in excess of normal running values. Accordingly, each bus transfer or reclosing reduces the life expectancy of the motor by some finite value…”.

A key factor is the dynamic conditions prior to and during the transfer, in particular phase angle and frequency difference between the motor bus and the new source. Traditional methods of measuring the transient stresses on motors during transfer such as V/Hz are discussed as well as alternative metrics such Torque Ratio. The relationship between Torque Ratio and closing angle (angle between motor bus and back-up source at breaker closing) is discussed, including analysis of previous research on this topic. Conclusions are drawn with regard to V/Hz and Torque Ratio as metrics to quantify the impact on the motor during bus transfer.

A number of motor bus transfer transition methods and modes are discussed and compared, including Closed Transition (make-before-break) and Open Transition (break-before-make) types.

The results of modelling of residual voltage transfer are presented and analysed, where the effect of different breaker closing phase angles on the peak transient current and torque are studied by varying the initial phase angle difference between the backup source and primary source. Motor currents during Residual Voltage Transfer are compared to normal motor start currents and prospective short circuit currents.

Thermal, Mechanical and Insulation Effects of Motor Start/Stop Operation

Similar to generators, motors can experience a range of damaging effects caused for frequent starting and stopping. Thermal cycling occurs each time a motor starts and stops, and thermal expansion and contraction of components can cause looseness in the stator and rotor core. Differential thermal expansion between conductors and insulation can cause de-bonding of conductor and insulation. Bending and bowing of the rotor cage has occurred due to thermal forces.

Motor starting and stopping will generate cycling mechanical forces which increase the likelihood of low cycle fatigue failure of rotor components.

The TB discusses various modes of potential insulation damage and failure caused by cycling operation such as deterioration of turn-to-turn insulation from circuit breaker switching transients, electromagnetic forces causing damage to endwinding insulation, and slot vibration damaging insulation.

Motor Starting Methods

The method for starting motors becomes extremely important where plant cycling is common. Direct On-Line (DOL), start/delta switching, external resistor and soft starting each have their own effects on motors, and come with varying degrees of cost and complexity and must be considered by users when designing electrical systems for plants expected to operate flexibly.

Review of relevant International Standards & Guidelines

International standards such as IEC 60034, ANSI/NEMA C50.41-2012, and NEMA MG-1 establish minimum design, manufacturing and test standards for electrical motors. Supplementary standards also deal with motor starting equipment such as Adjustable Speed Drives (ASD). American Petroleum Institute API 541 standard covers large (>375kW) induction motors, and was developed for critical motors for the petroleum, chemical, and other industry applications.

Conclusions and recommendations

A number of recommendations are made for users for both purchase of new motors and operation of existing motors. Recommendations for new motors to cater for cycling operation are proposed for the feasibility stage, motor specification, design, manufacture and testing, and for motor ancillary equipment. Recommendations are also made for motor maintenance, operation and condition monitoring.