Mobile substations incorporating HV GIS

CIGRE Working Group B3.41 was tasked with an investigation and assessment of mobile, prefabricated and build-off-site substations for the following scope:

• Drivers for deployment of mobile substations

• Benefits of using mobile substations.

• Experience of implementation and operation, including relevant case studies

• Applicability of existing standards

• Guidelines for specification and design

Members

Convenor (UK)

P. FLETCHER

Secretary (DE)

S. CRAY

F. DISSON (FR), F. GEBHARDT (DE), A. GOYVAERTS (BE), P. GROSSMANN (US), J. LOPEZ-ROLDAN (AU), D. MAGANTO (ES), C. MARTIN (BE), V. MURPHY (IE), N. OTAKA (JP)

Scope of Working Group

In recent years several utilities have reported on the use of ‘mobile’ substations employing a high level of off-site construction. A number of specific objectives have been described, such as the ability to quickly substitute a failed transformer in an emergency; however, the underlying aim is the ability to provide new, extended or replacement substation facilities either at short notice and/or with a reduced site construction period compared with traditional solutions. There is a growing interest in such ‘build off-site’ solutions as transmission and distribution owners come under pressure to respond rapidly to changing user demands. The ability to respond to these demands is one element in delivering smarter grids for the 21st Century.

Mobile substations generally, although not exclusively, utilise GIS technology with many designs based on compact switchgear assemblies with the addition of integrated protection and control facilities. Thus, in addition to individual standards covering the design and testing of the functional components of the substation, the following existing standards are partly relevant to mobile substations:

- IEC62271 High-voltage switchgear and controlgear - Part 202: High voltage/low voltage prefabricated substation

- IEC62271 High-voltage switchgear and controlgear - Part 205: Compact switchgear assemblies for rated voltages above 52 kV

These standards, however, do not necessarily consider the specific requirements for design, construction and testing of mobile substations and it was identified that recommendations were required on this issue.

In some circumstances, depending on the application, it may not be appropriate for mobile substations to fully comply with conventional standards regarding, for example, foundations, environmental conditions or testing requirements. The work of CIGRE WG B3.41 aims to give recommendations on how to consider these topics.

The early adopters of mobile substation technology have now gained valuable experience regarding the design, testing, implementation and use of mobile substations and CIGRE Study Committee B3 decided that it would be valuable to capture this experience. WG B3.41 was established to undertake this task and the resulting Technical Brochure presents the conclusions of the work.

The main focus of the Technical Brochure is on the incorporation of GIS technology into mobile substations. The WG does not aim to give guidance on specific design and testing requirements for other types of equipment such as transformers or Protection & Control (P&C).

Structure and content of the Technical Brochure

The scope and main results of this Technical Brochure includes the contents below.

- INTRODUCTION ON MOBILE SUBSTATIONS:

- What is a mobile substation?

- Types of mobile substations

- Development of technologies to enable wider use of mobile substations

- Drivers and benefits of mobile substations

- GUIDELINES FOR SPECIFICATION AND DESIGN OF MOBILE SUBSTATIONS

- Transport/road regulations

- Mechanical requirements

- Design requirements specific to location

- Deployment

- TESTING OF MOBILE SUBSTATIONS

- Introduction to testing

- Variation in test requirements between standards and mobile substations

- Recommendations for testing of mobile substations

- Summary of test requirements

- ASSET MANAGEMENT

- Storage

- Maintenance

- Asset life

- Gas handling and gas management

- General considerations for redeployment

- EXPERIENCE OF MOBILE SUBSTATIONS

- Summary of case studies

- In-service experience

- RECOMMENDATIONS FOR THE APPLICABILITY OF EXISTING STANDARDS

- CONCLUSION

- APPENDIX: CASE STUDIES

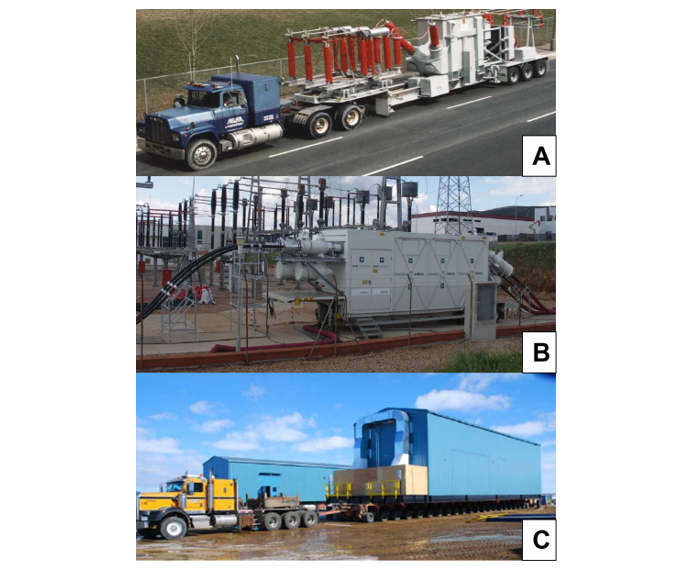

Chapter 1 presents the concept of mobile substations and the motivation to design a mobile substation instead of a conventional substation. The WG established 3 categories of mobile substations:

- Type A mobile substation: “short term emergency type unit” typically used for:

- Unplanned deployment to replace failed equipment, bays or the complete substation

- Planned deployment to support maintenance works or to provide short time network enhancement.

- Type B mobile substation: “intermediate type unit” typically used for:

- Unplanned deployment to replace failed equipment, bays or substations (longer deployment time than emergency type)

- Planned deployment to support infrastructure works or to provide network enhancement for a longer period of time.

- Type C mobile substations: “semi-stationary type unit” typically used for:

- Planned deployment as an alternative to a conventional substation where resources (e.g. skilled labour) are not readily available or costs are high

- Planned deployment as an alternative to a conventional substation when site works are difficult or impossible (eg offshore substation).

Figure 1 shows an example of the three types of mobile substations.

Figure 1 - Examples of mobile substations type A, B and C

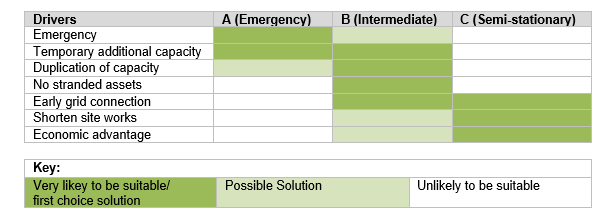

The drivers for selecting each type of mobile substation are summarised in table 1

Table 1 - Overview of Drivers in relation to Types of Mobile Substation

Chapter 2 presents some guidelines for the specification and design of mobile substations emphasizing the specific conditions not considered in conventional substations such as the requirement for relocation, the road regulations, the mechanical vibrations during transport, the compromise between clearances onsite and carriage size and the earthing connections when installing the mobile substation inside or outside an existing substation.

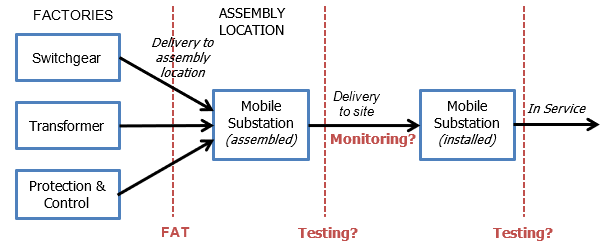

Chapter 3 discusses the specific requirements for the testing of mobile substations. For example a conventional substation requires the testing of the HV components both at the factory (FAT) and onsite. Mobile substations might require different considerations of testing, for example due to additional transport between factory, assembly location and final destination, or in order to enable a shortening of the installation and commissioning time on site. This can be seen at figure 2.

Figure 2 - Testing Locations for Mobile Substations

The WG gives some considerations for the testing of mobile substations regarding the balance between the impact of the testing on the cost and the deployment time and the risk appetite of the user depending on their circumstances (as in the case of emergency situations). This is shown in figure 3.