Sustainability of OHL conductors and fittings – Conductor condition assessment and life extension – Vol. 1

Members

Convenor (FR)

C. ROZE

Secretary (US)

N. FULK

Secretary (US)

J. HAVEL

P. BUEHLMANN (CH), G. DIANA (IT), G. FLOREA (RO), T. FURTADO (BR), C. GARESCI (IT), K. HALSAN (NO), B. JENSEN (DK), S. LALONDE (CA), S. LANGLOIS (CA), S. MUSHABE (ZA), K. SCHILLAI (CH), J. UNTERFINGER (DE), A. VAN DER WAL (NL), N. XYDAS (GB), T. YAMANAKA (JP)

Corresponding Members

U. COSMAI (IT), W. GHOUAT (CA), D. HAVARD (CA), S. HEURTAULT (FR), T. KAVANAGH (IE), H.J. KRISPIN (DE), M. LEE (AU), A. MANENTI (IT), J. Mc CORMACK (AU), A. MOLLOY (GB), T. OLUWAFEMI (CA), J.P. PARADIS (CA), A. RONDINEAU (FR), N. SAHLANI (US), H. SAKAI (JP), D. SUNKLE (US), W. TROPPAUER (AT), S. UEDA (BR), P. VAN DYKE (CA), C. WINTER (DE), L. YANG (CN), X. YANG (CN)

Reviewers

A. ANAND (IN), V. LOVRENCIC (SI)

This Technical Brochure (TB) (Volume 1) provides the state of the art for conventional conductors and attached fittings regarding:

- Ageing mechanisms for conductors

- Tests on new and aged components, diagnostic sensors, tools and monitoring

- Asset management practices

The aim is to give a complete state of the art on the subject. The new information concerns:

- Corrosion mechanism and classifications

- Sequential test proposal

- Summary of tests for aged conductors

- State of the art on monitoring corrosion and fatigue

- Practical examples: joint failure analysis, assessment of the safe bending amplitude at specific tensions, sequential tests on conductors, spacers, etc.

- Overview of asset management practices and an average lifetime per component.

Volume 2 will provide recommendations including use of test results, inspection, maintenance and replacement of conductors and fittings with case studies as examples.

Ageing mechanisms

Corrosion

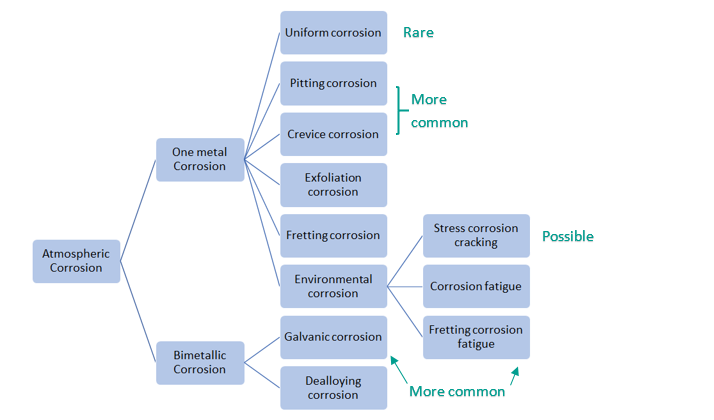

The assessment and prediction of conductor corrosion (Figure 1) is difficult due to its complex geometry, variety of materials, and environments.

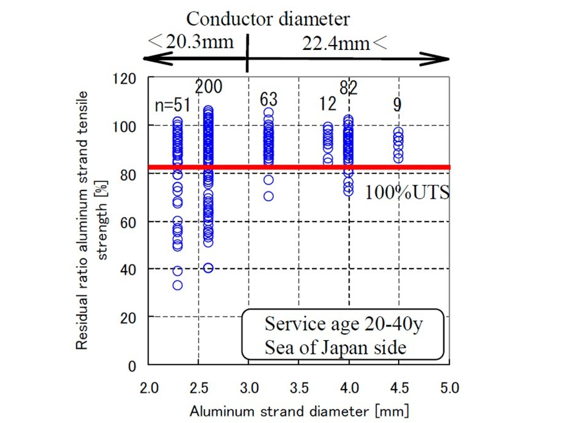

A greater number of aluminium layers surrounding the core will better protect the core against penetration of pollutants but also retains more water and pollutants. Studies show it is better to design conductors intended for corrosive environments with strand diameters above 3 mm (Figure 2). Greasing is a physical barrier for moisture, salts and pollutants until it decreases over time.

In joints, temperature accelerates corrosion due to increased contact resistance that can lead to thermal runaway. Loosening or fatigue is of greater concern for other types of fittings than corrosion.

Impacting environmental factors are:

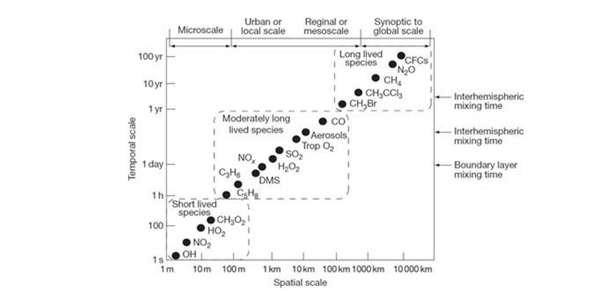

- Pollutants: chlorides ions (sea), sulfates ions (industrial), distance from emission (Figure 3).

- Rainfall, humidity, wet and dry cycles, temperature, possibly magnetic field.

Parameters to look at are zinc thickness (steel), residual tension strength, pitting depth, ductility, electrical resistance (aluminium), diameter of strands and cable, grease.

Figure 1 – Type of corrosion for conductors

Figure 2 - Relationship between the strand diameter and the residual ratio of aluminium strand tensile strength [Ito et al. 2012]

Figure 3 - Spatial and temporal scales of variability for atmospheric main constituents [Seinfeld and Pandis, 2016]

Fatigue

This topic is largely covered in literature but still not so well understood. This section is a synthesized review on state of the art, highlighting essential aspects, gaps in knowledge, and on-going research. The primary types of vibration are described: aeolian vibration, wind induced oscillation on bundles, and galloping.

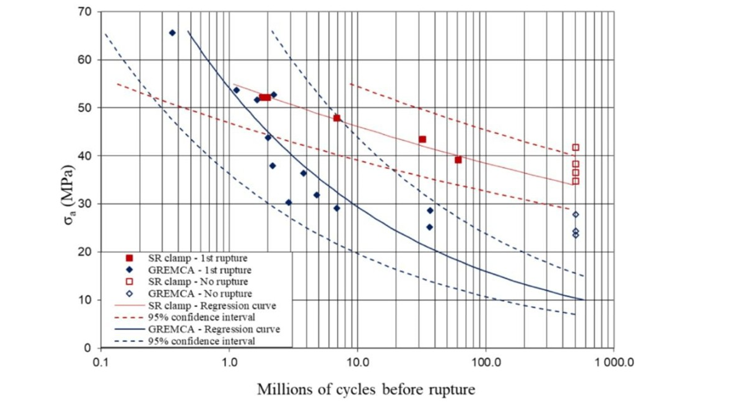

About fretting fatigue behaviour (aeolian vibration), there is no exact model for fatigue endurance determination. The endurance limit is determined as maximum vibration amplitude applied without strand failure below 500 Megacycles (Figure 4).

Mitigation measures are linked to motion control systems using appropriate placements of fittings for each of the three main vibration phenomena.

A survey revealed that only 6% of TSOs use the safe border line method to evaluate conductor residual life, while the majority (59%) adopted the bending strain criteria to assess the induced damage severity on conductors. Most data available are from ACSR conductors (Aluminium Conductor Steel Reinforced with round wires) in short radius metallic clamps.

Other degradation mechanisms

They can be divided in two categories. Those which concern local degradation (loosening - Figure 5, melting due to lightning, bird-caging, damage due to gun shots, erection or maintenance damage, and damage due to clashing) and mechanisms that concern deterioration to the whole conductor (plastic elongation, creep, annealing).

There is still much unknown about degradation mechanisms, and even more for the combination of phenomena.

Figure 4 - ACSR Crow S-N fatigue curves with different clamp configurations [Paradis and Van Dyke, 2020]

Figure 5 - Abrasion damages of the conductor due to clamp slip movements

Tools to appreciate ageing

Classifications

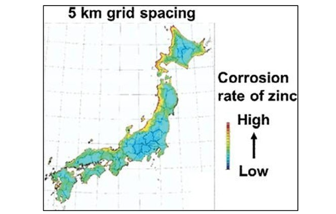

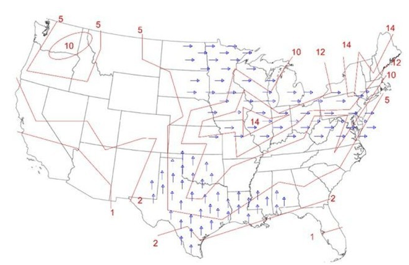

Corrosion classification of the atmosphere can be made by multiple methods (Table 1). Classification results are represented by corrosion rates at different sites and can be shown on a map as demonstrated in Figure 6. For fatigue, there is no clear mapping method, but a wind and ice map is provided for the United States (Figure 7).

Figure 6 - Example of corrosivity map for zinc in Japan

[Tatsuoka et al., 2019]

Figure 7 - Freezing rain and prevailing wind direction in the central U.S

| Corrosion | Fatigue | Creep, estimation of ice loading, annealing | |

|---|---|---|---|

| Availability of models for conductors and fittings | Rare | Yes | Some |

| Usage of models | No feedback | For design or to check design when damage appears. On-going research to develop numerical tools listed in TB. | Not for ageing evaluation |

Tests

All tests in TB are summarised for conductors and fittings including type of tests, testing standards, purpose, relevance, and limitations.

Tests on new samples

To assess ageing on a new design, experience, laboratory tests, and installation on pilot lines are used. Tests are summarised for new conductors and new fittings including type of tests, testing standards, purpose, relevance, and limitations.

It is difficult to predict long-term effects with the few short-term ageing tests available. Tests for specific conditions in corrosion, wind, and high altitude are provided in TB.

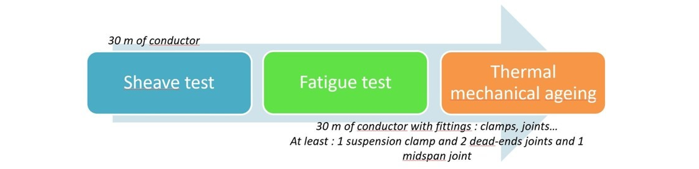

This TB proposes a new approach for sequential testing (Figure 8 and Figure 9) and two examples: one for conductors, another for spacers.

Figure 8 - First step of sequential test - tests on 30 m of conductor with fittings

Figure 9 - Split in three samples before tests on each sample

Tests on aged components

Recommendations are provided for sample selection, recording information in the field, collecting, marking and labelling, transporting, documenting, and preparing in laboratory.

On-site tools

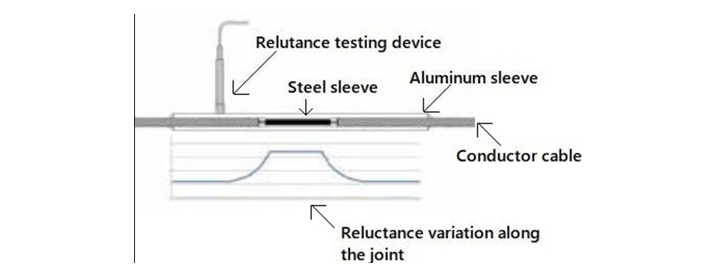

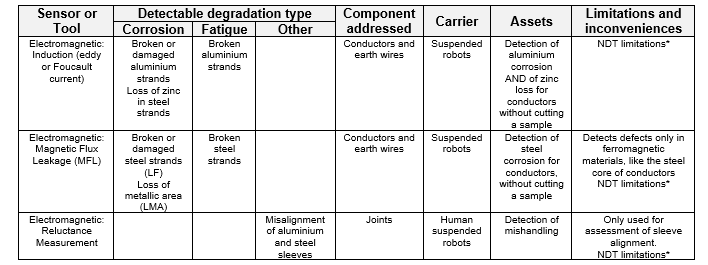

A review of sensors is included in the TB, covering optical, infrared, UV, acoustic, radiographic, electromagnetic, temperature, and motion sensors (Example Figure 10).

Figure 10 - Determination of a reluctance chart along the longitudinal axis of a mid-span joint

[C. Wallace, M. Taylor, 2013]

Diagnosic tools are evaluated with infrared thermography, electrical resistance measurement, boroscope, robotic inspection with electromagnetic sensors (Table 2), and radiography (Figure 11).

Figure 11 - Image of a properly installed joint - Radiography with Gamma ray apparatus

[Nogueira et al., 2017]

Table 2 - Example of summary for electromagnetic tools

Monitoring needs to be combined with meteorological data for overhead lines. There is limited equipment available that is dedicated to conductors and fittings due to height, electric and magnetic field, and environmental conditions. Actual corrosion monitoring is designed for flat structures. Ice and fatigue monitoring are possible. The most recent devices for fatigue afford real time measurement spanning more than two months.